SELECT DISTINCT shop_view_active_item.*

FROM shop_item_has_category

INNER JOIN shop_view_active_item ON (

shop_view_active_item.company = shop_item_has_category.company AND

shop_view_active_item.shop_code = shop_item_has_category.shop_code AND

shop_view_active_item.language_code = shop_item_has_category.language_code AND

(

shop_item_has_category.item_no = shop_view_active_item.item_no

)

)

WHERE (shop_item_has_category.category_line_no = 20000)

AND shop_view_active_item.language_code = 'ENU'

AND shop_view_active_item.company = 'DESOI'

AND shop_view_active_item.shop_code = 'B2B'

AND shop_item_has_category.company = 'DESOI'

AND shop_item_has_category.shop_code = 'B2B'

AND shop_item_has_category.language_code = 'ENU'

AND shop_item_has_category.category_shop_code = 'B2B'

The entered access data are not correct. Please try again.

Become a customer

You do not have online access yet? Request your access data here.

Add Item to

Shopping Basket

Add all selected Items

to Shopping Basket

Remove Item from Shopping Basket

Add item to favorites

Remove Item from Favorites

Stock Outage

Make a Preorder

Insufficient Stock

Item well stocked

Article in delivery

This item is part of a current campain

Polymeric filling material (injection resin)

Injection resins can consist of one or two components that react chemically with each other. Initiators and accelerators are mixed in as additional components as required. By injecting polymeric filling materials, various injection targets are pursued, such as sealing of components or the non-positive connection of components. For this purpose, different packer types from the DESOI quality range can be used to successfully carry out an injection task.

Polymeric filling material (Injection resin)

open PDF

Application aims for the filling of cracks

- Inhibition or prevention of access of corrosion-promoting substances in concrete components by cracks (closing)

- Force-locking connection of cracked components

- Removal of crack-related leaks (sealing)

- Making a limited expandable connection of crack flanks (limited expandable connection)

Instructions for use

- Filling in the area of cavities can be provided for comparable application aims

- Areas of application of the crack fillers and fillers depend on the moisture content of the cracks and the crack widths

- Injection pressure of the crack fillers should be limited according to the component requirements and tasks for execution

Example: C 20/25 - 25/3 x 10 bar = approx. 80 bar

Material to be used

- Epoxy resin

- Polyurethane

- Quick-foaming polyurethane

- Acrylate gel (with special certificate of suitability)

Demands on the injection devices

- Simple operation and verifiability of functionality

- Low susceptibility

- Injection pressure adjustable (can be limited depending on crack filling material, component properties and area of application)

- Easy cleaning and maintenance

Suitable objects

- Residential and industrial buildings

- Civil engineering structures

- Underground and canal construction

- Hydraulic structures

- Traffic structures

Information

Cracks have to be filled completely, i.e. at least up to a filling degree of 80 % of the component cross-section to be filled.

(Observe the specifications of the planner)

Demands on the bore packers

- Compatibility of materials (packer components) with fillers used

- Reliable fixing in the component

- Corrosion resistance of the parts remaining in the structure

- High pressure resistance

- Possibility of shutting off

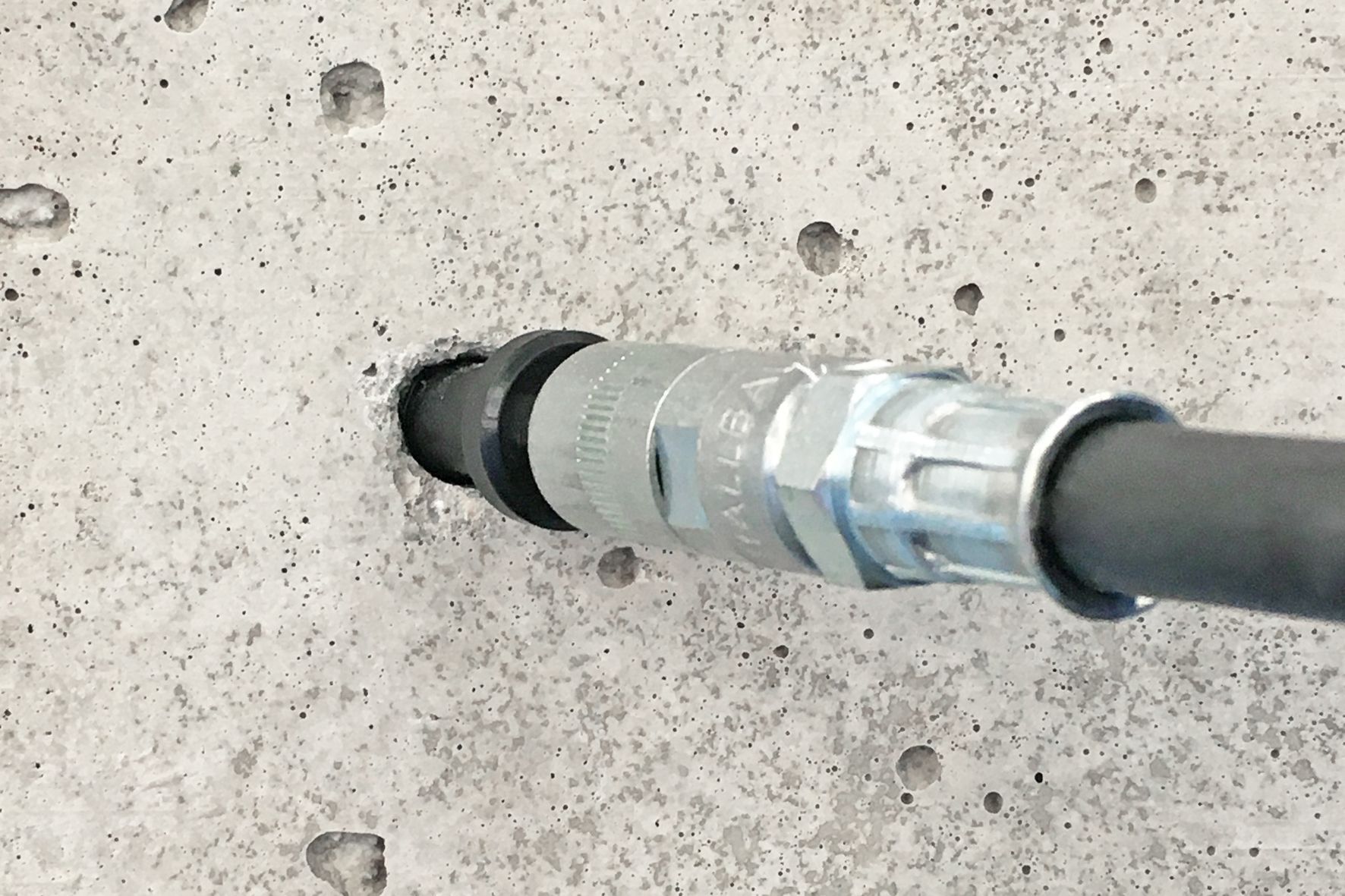

Placing of the bore packers

- Packer distance depends on component thickness(½ component thickness = packer distance)

- Drill alternately at an angle of 45° to the crack to hit the crack in the middle of the component (depending on the object)

- Clean (e. g. with compressed air) and prepare the boreholes, depending on the filler

- Set and clamp packer (in the case of dry cracks, prewet crack flanks)

- Close crack with insulating material, leave crack end free for venting and level control, at the highest point for vertical cracks

- Inject the packer until the crack filler emerges from the next packer, reinject each packer within the processing time of the crack filler

- After the injection the injection packers are removed or non-corrosive parts can remain in the building (agreement with the builder required)

- Seal boreholes

Plugging

- The insulation prevents the filler from escaping during injection

- Repair of leaks with fast-reacting substances

Desoi Sealing cone system

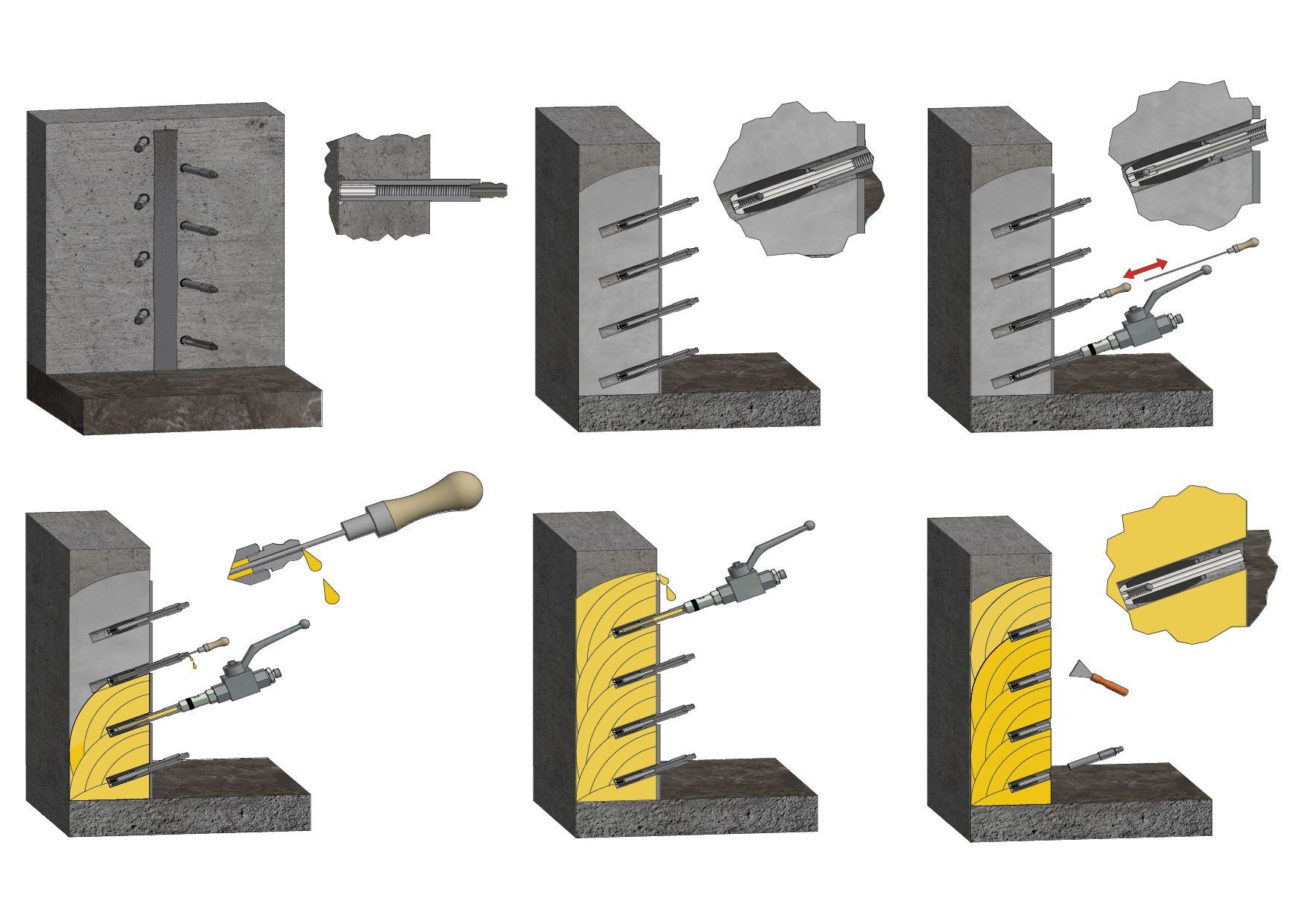

Procedure according to ZTV-ING

According to ZTV-ING*, cracks must be fi lled in such a way that the escape of water and / or air during the injection is ensured. In order to ensure that a crack is completely fi lled with injection material, the injection process must be continued until the material emerges from the next packer. With the help of the round head and pan head nipples with sealing cone, this requirement can be met without additional effort.

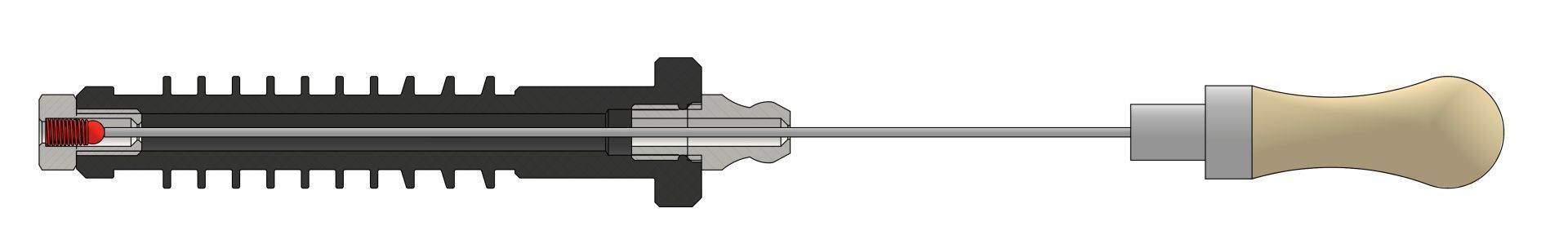

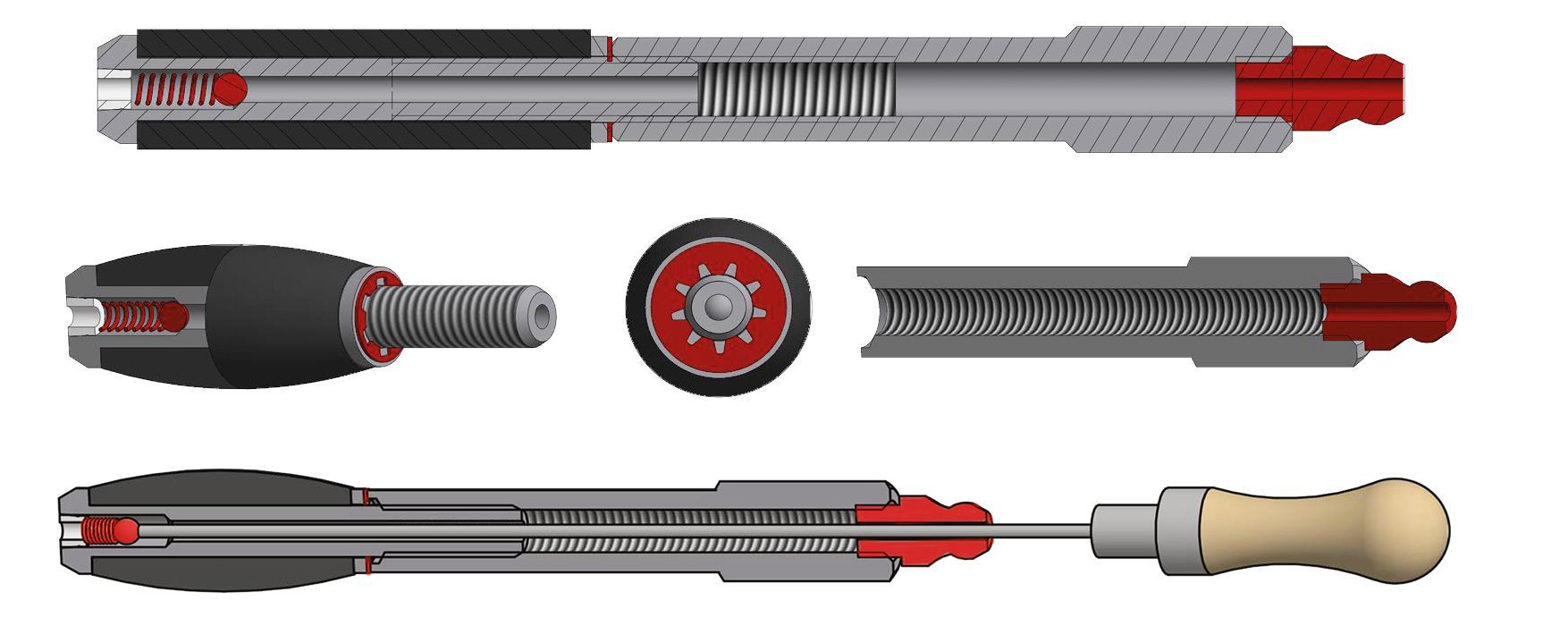

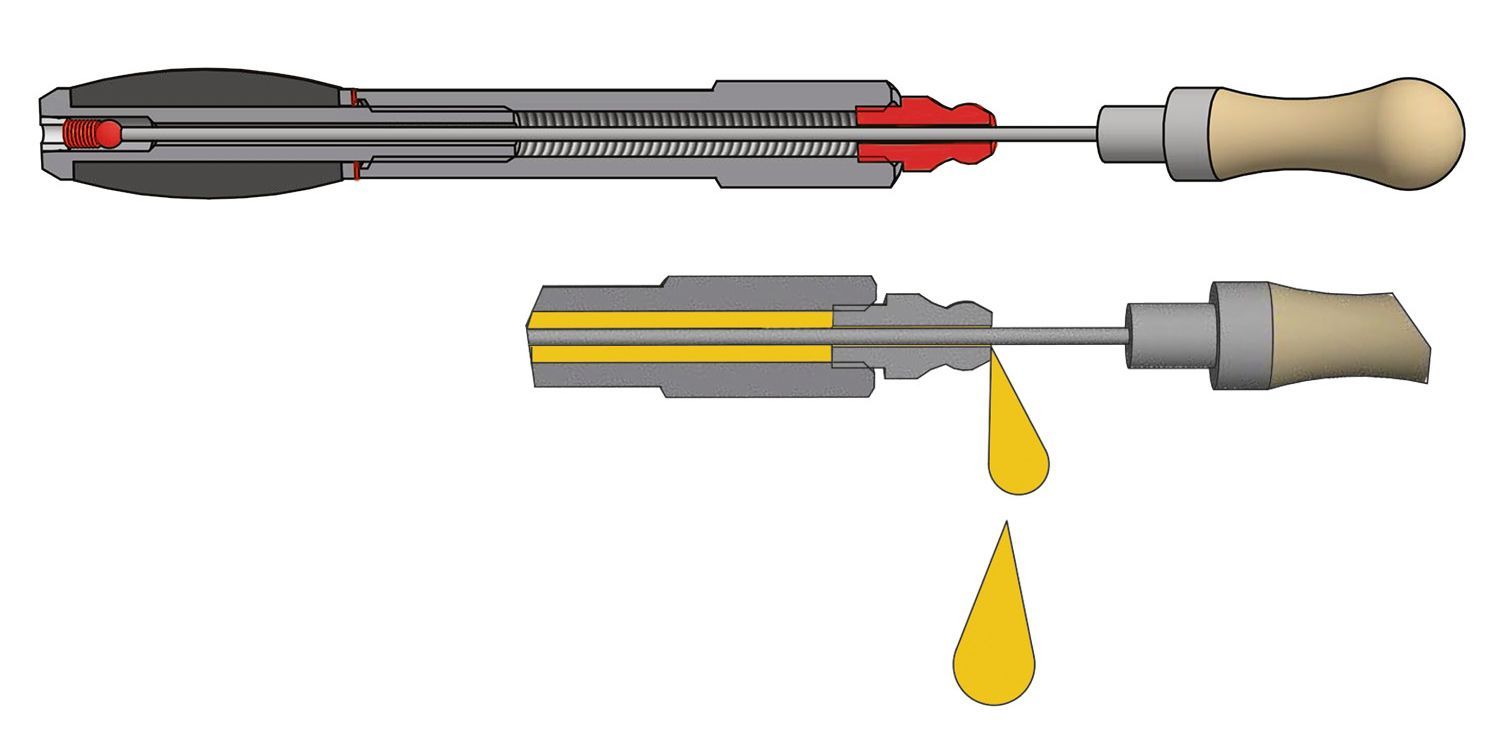

One day lamella drive-in packer with check valve

1-day steel packer with special retaining retaining

Procedure

- Alternate drilling

- Clean and prepare boreholes

- Set packer

- Screw on round head nipple

- Insert deairing tool

- Connect ball valve

- Inject until material emerges from packer with deairing tool

- Repeat procedure

- Inject until material escapes from uninsulated crack end

- Post-injection within the processing time

- Remove thrust piece

- Fill boreholes with mortar and close them

Advantages / Information

- All working steps can be carried out on one day

- Due to the integrated check valve no injection material may run back through the packer

- The thrust piece can be removed directly after the injection

- The borehole can be sealed with appropriate material

- The sealing system keeps the clamping rubber tensioned

- Opening pressure approx. 10 – 15 bar

- The exact bore diameter has to be observed for safe high-pressure injection

- Nominal diameter = borehole diameter, exception Ø 13 mm = 14 mm borehole

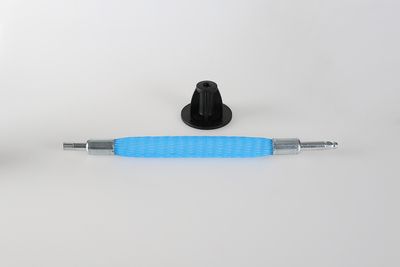

deairing tool

For deairing of 1-day packers by using the nipples with free passage.

Advantages

» The special material properties of the adhesive packer promote the bonding between the adhesive

and the adhesive surface of the packer. Depending on the underground, the adhesive packers withstand high pressures.

- Time and material savings

» The insulating material only needs to be applied over the crack

» The adhesive is applied very thinly on the adhesive surface of the packer

Application range

- On non-wet undergrounds

- Structural elements with dense reinforcement

- Prestressed concrete

Placing of the adhesive packers

- Roughen the surface on both sides of the crack depending on the structural element, remove any debris or loose particles, dust etc.

- Distance between packers depends on thickness of structural element (normally: thickness of structural element = distance between packers)

- Keep the injection canal free by driving a greased steel pin into the crack

- Seal the crack surface with sealing material also embedding the flanges of the adhesive packers but stop before the end of crack for deaeration

- Remove all steel pins and screw a round head nipple on the first packer to be injected

- Inject the packer until injection material comes out of the adjacent packer, screw in round head nipple

- After the injection material has cured remove packers and sealing material

- Recondition surface

Information

- Adhesive packers are also available in steel

general

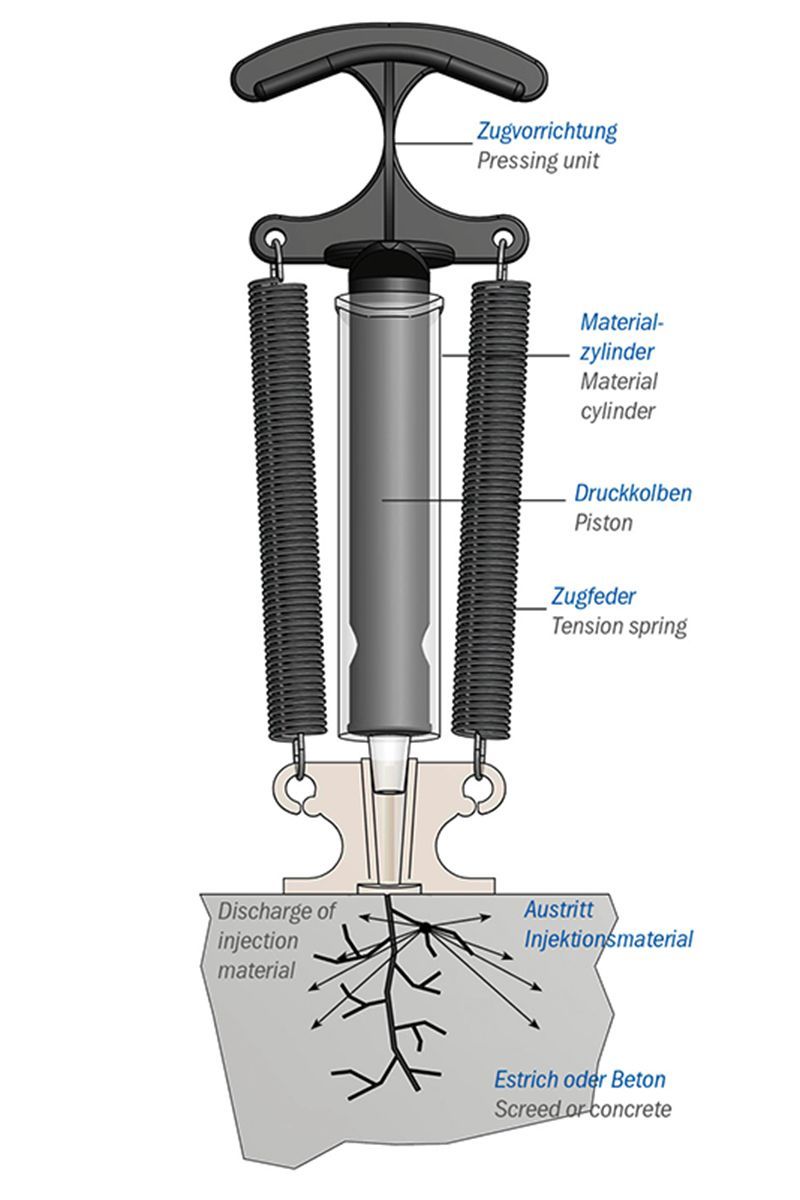

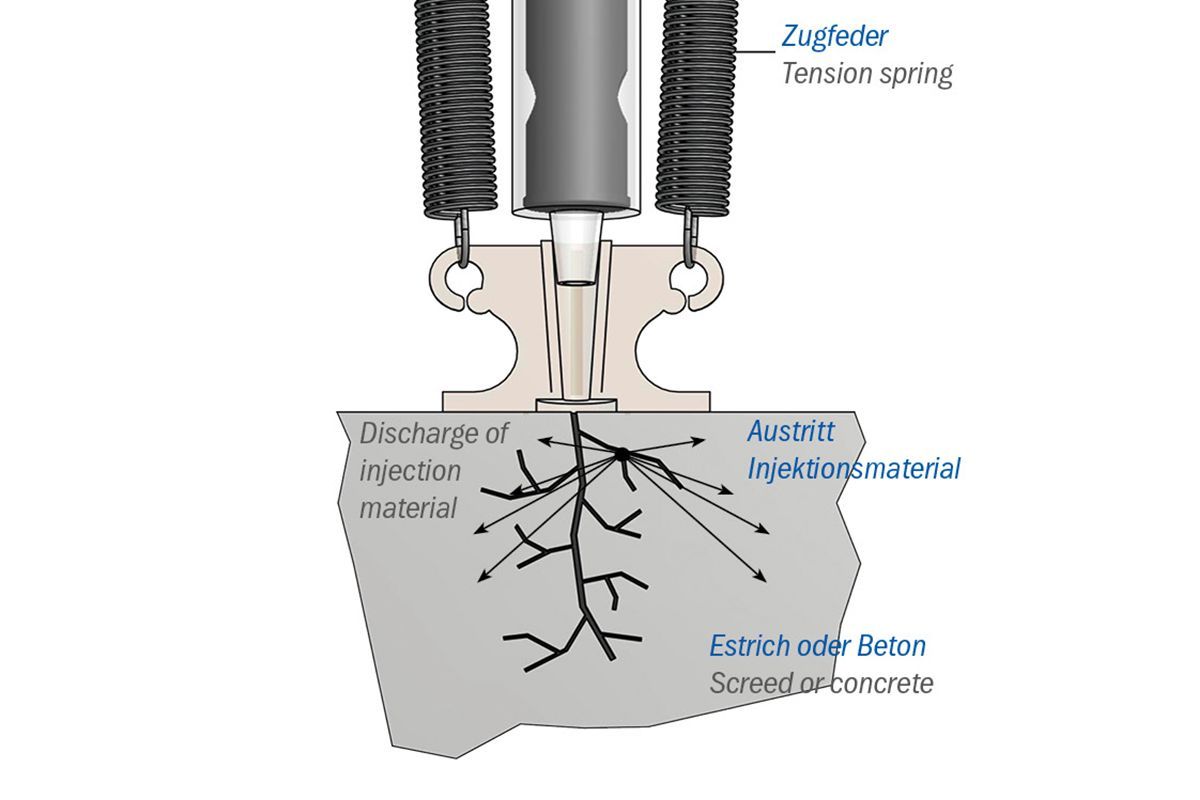

The self-injecting device is used when the injection process has to be carried out at low pressure (approx. 1 bar) and over a longer time period to ensure a successful result (e. g. with very fi ne cracks).

Material to be used

- Cement suspension

- Epoxy resin

- Polyurethane

Advantages

- Injection without machines

- Simple working principle

- Easy visual monitoring of consumption

- Several injection devices can be used at the same time at various places

- Can be used overhead

General operation

- Hook the tension springs to the packer

- Draw in injection material using the material cylinder

- Insert material cylinder into the cone

- Place the pressing unit on the piston

- The injection process starts, the material consumption is indicated at the scale

- Repeat fi lling process if necessary

ADHESIVE PACKER

- Mark the distance between packers

- Grease a steel pin and drive it into the crack

- Bonding with Klebfix

- Apply adhesive (sealing material) on the adhesive surface of the packer

- Place packer

- Seal crack surface up to 3 – 5 cm from the end of crack

- Bonding with hot glue

- Apply adhesive (sealing material) on the adherend of the packer and slip the packer over the steel pin and press the packer on the concrete

- Seal possible open cracks between the injection devices with adhesive

- Remove steel pin from packer

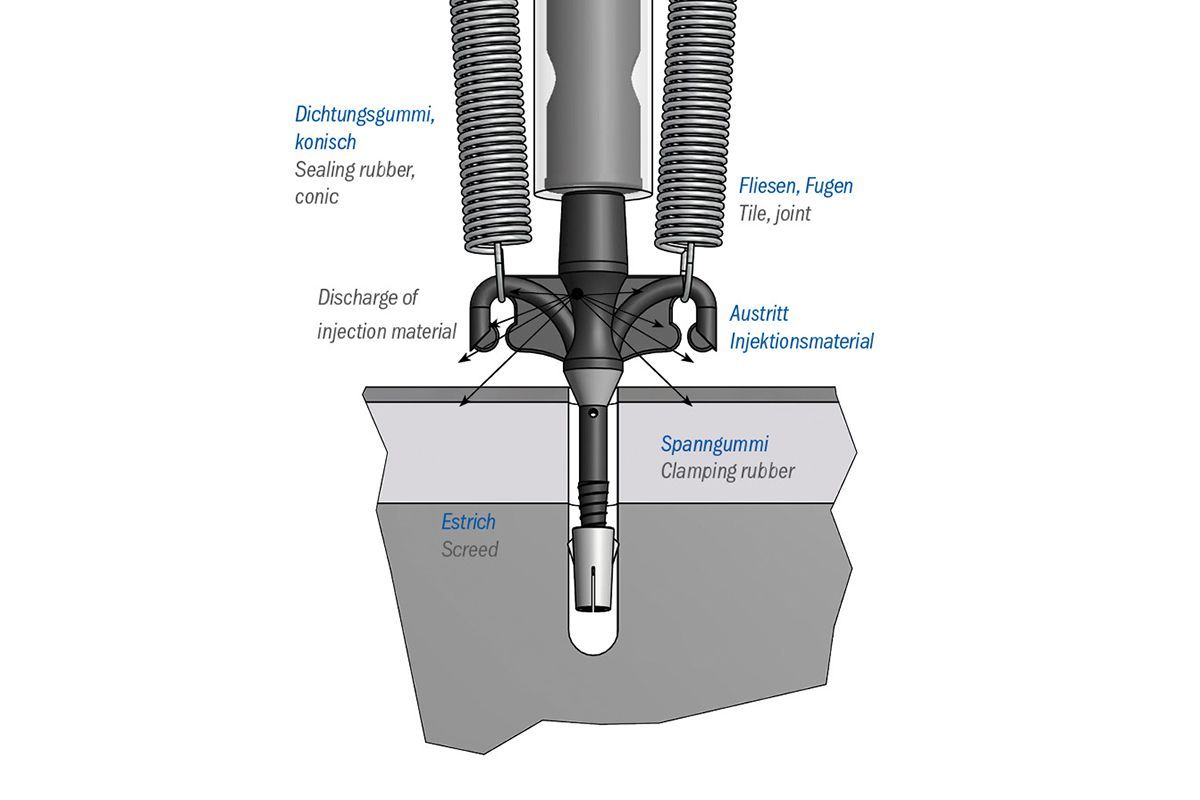

MULTI TILE PACKER

- Mit dem Spezialbohrer Ø 6 mm in die Fugenkreuze der hohlliegenden Fliesen bohren

- Remove drill dust

- Clamp multi tile packer in the drill hole

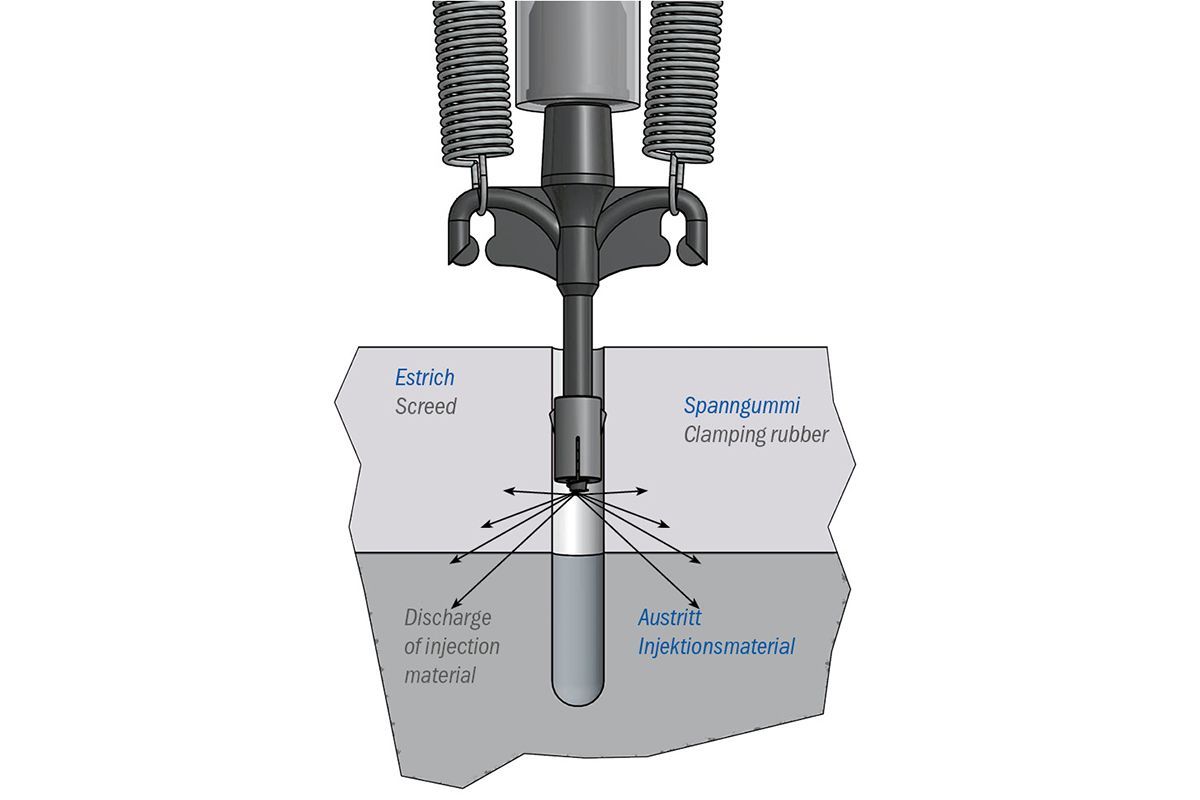

SCREED SCREW PACKER

- Make a drill hole Ø 6 mm through the hollow screed using a special drill

- Remove drill dust

- Clamp screed screw packer in the drill hole

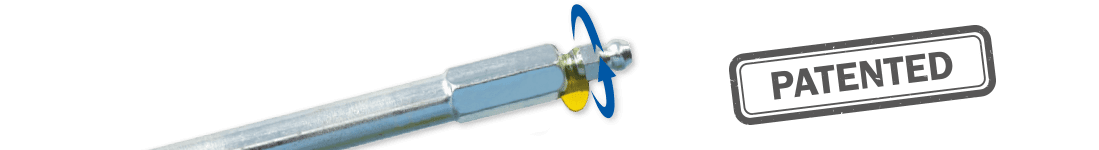

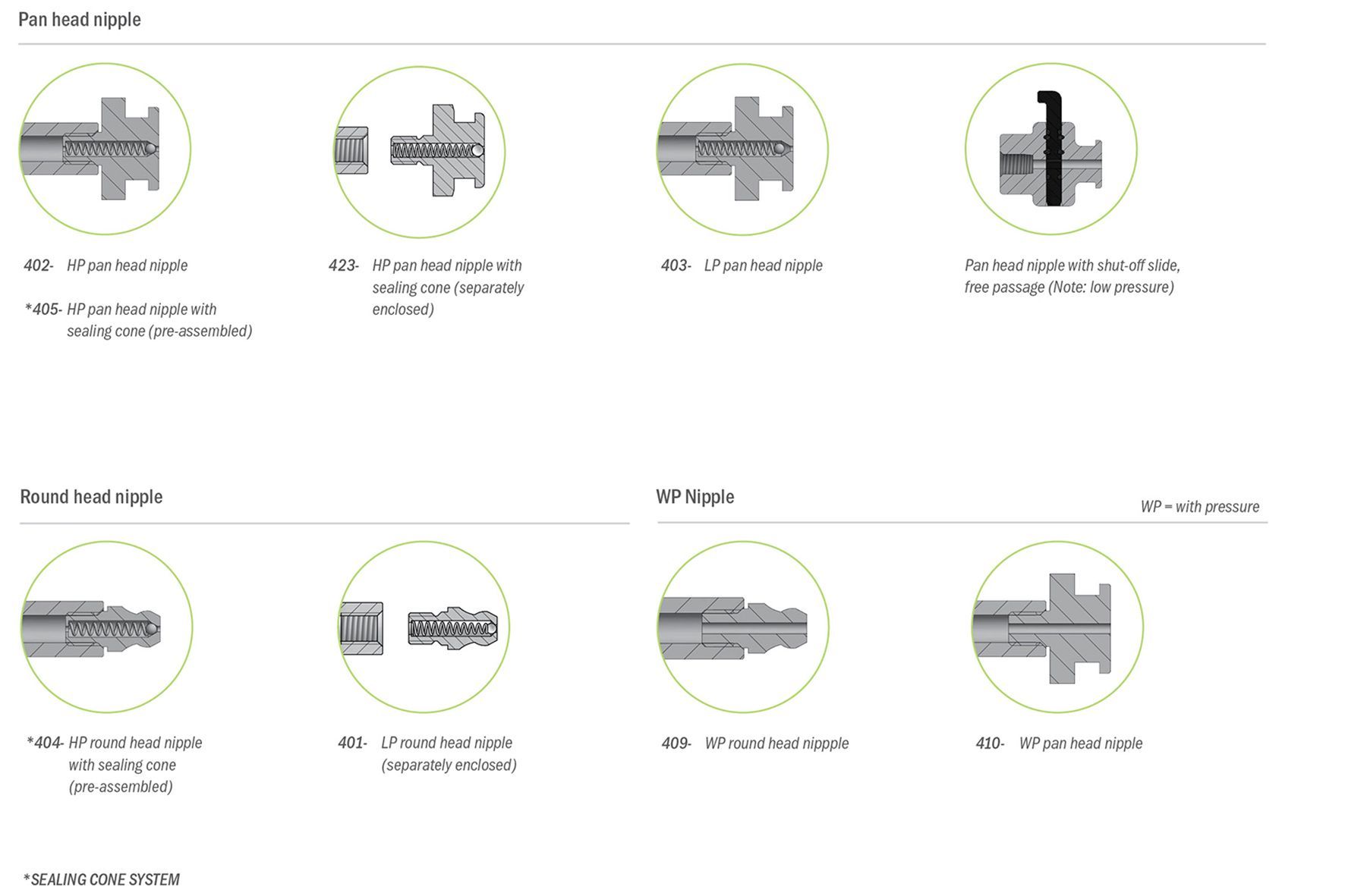

For the processing of reaction resins, the injection packers are equipped as standard with a high-pressure (HP) round head nipple with sealing cone. The opening pressure is approx. 15 – 20 bar, i. e. at this pressure the ball valve opens and the flow of the crack filler into the component begins.

Another possibility is to inject in the low-pressure process with an opening pressure of approx. 2 – 3 bar using the low-pressure (LP) nipple. As an alternative, the pan head nipple can be used, for which a sliding coupling is required on the machine side. The nipple with shut-off slide is a variant in which there is no opening pressure to overcome and thus the crack filler can flow unhindered. The use of high or low pressure processes depends on the requirements of the injection.

Procedure according to ZTV-ING – Nipple with sealing cone (pre-assembled)

- For delivery, the HP nipples with sealing cone are hand-tightly screwed onto the steel packers

- Clamp steel packer in the borehole

- Only tighten the HP nipple of the steel packer that is injected first

- Loosen the HP nipples of the other steel packers by one turn

- Inject the first steel packer until filler emerges from the second steel packer

- Tighten the HP nipple of the second steel packer

- Inject second steel packer until filler exits third steel packer

- Tighten the HP nipple of the third steel packer, etc.

- Post-injection is part of the injection procedure

Advantages

- Complete filling of the crack or cavity

Wir brauchen Ihr Einverständnis!

Wir benutzen Drittanbieter, um Videoinhalte einzubinden. Diese können persönliche Daten über Ihre Aktivitäten sammeln. Bitte beachten Sie die Details und geben Sie Ihre Einwilligung.

Mehr Informationen

Externe Medien Akzeptieren

Wir brauchen Ihr Einverständnis!

Wir benutzen Drittanbieter, um Videoinhalte einzubinden. Diese können persönliche Daten über Ihre Aktivitäten sammeln. Bitte beachten Sie die Details und geben Sie Ihre Einwilligung.

Mehr Informationen

Externe Medien Akzeptieren

Wir brauchen Ihr Einverständnis!

Wir benutzen Drittanbieter, um Videoinhalte einzubinden. Diese können persönliche Daten über Ihre Aktivitäten sammeln. Bitte beachten Sie die Details und geben Sie Ihre Einwilligung.

Mehr Informationen

Externe Medien Akzeptieren

Wir brauchen Ihr Einverständnis!

Wir benutzen Drittanbieter, um Videoinhalte einzubinden. Diese können persönliche Daten über Ihre Aktivitäten sammeln. Bitte beachten Sie die Details und geben Sie Ihre Einwilligung.

Mehr Informationen

Externe Medien Akzeptieren