The thread unscrewing units (TUU) are used to demould threads in plastic and metal powder injection-moulded parts (MIM parts). They are mounted to or installed in the tool and ensure an absolute repeatability.

Each of the TUU is assembled from individual standard modules for the specific use. For this purpose, the customer must communicate all requirements/conditions, such as drive type (hydraulic/electric), centre distances (in the case of multiple TUU), thread types, threaded sections (drawings, dimensions, 3D model), thread direction (right/left), material of the injection-moulded part, space available (solution: angle TUU) etc., see request form.

Info: The most complicated designs are feasible.

DESOI makes it possible.

Wir brauchen Ihr Einverständnis!

Wir benutzen Drittanbieter, um Videoinhalte einzubinden. Diese können persönliche Daten über Ihre Aktivitäten sammeln. Bitte beachten Sie die Details und geben Sie Ihre Einwilligung.

Mehr Informationen

Externe Medien Akzeptieren

Wir brauchen Ihr Einverständnis!

Wir benutzen Drittanbieter, um Videoinhalte einzubinden. Diese können persönliche Daten über Ihre Aktivitäten sammeln. Bitte beachten Sie die Details und geben Sie Ihre Einwilligung.

Mehr Informationen

Externe Medien Akzeptieren

Wir brauchen Ihr Einverständnis!

Wir benutzen Drittanbieter, um Videoinhalte einzubinden. Diese können persönliche Daten über Ihre Aktivitäten sammeln. Bitte beachten Sie die Details und geben Sie Ihre Einwilligung.

Mehr Informationen

Externe Medien Akzeptieren

Wir brauchen Ihr Einverständnis!

Wir benutzen Drittanbieter, um Videoinhalte einzubinden. Diese können persönliche Daten über Ihre Aktivitäten sammeln. Bitte beachten Sie die Details und geben Sie Ihre Einwilligung.

Mehr Informationen

Externe Medien Akzeptieren

SINGLE THREAD UNSCREWING UNITS

The single TUU is used to demould single internal threads of any kind. It is powered hydraulically or electrically. The electric drive consists of a servo motor as well as an operating and control unit.

Double THREAD UNSCREWING UNITS

The centre distance of the threads is important. Different types of threads as well as thread cores of unequal lengths can be demoulded at the same time.

Fourfold thread unscrewing unit

For the standard version of the fourfold TUU the threads must show the same axial alignment. The types and thread pitches may be different but must be unscrewed in the same direction of rotation – right or left. Special units for different rotational directions are feasible.

Eightfold thread unscrewing unit

The modular design allows the realisation of all possible variants of a TUU. The models shown here are examples of standard units. In principle, there is a solution for every different requirement.

Angle thread unscrewing unit

Limited space? No problem with angle TUUs. They are the answer to difficult space conditions.

Accessory – Flow Indicator

This visual control unit is installed in the cooling circuit of the core cooling system. If the impeller rotates, everything's fine.

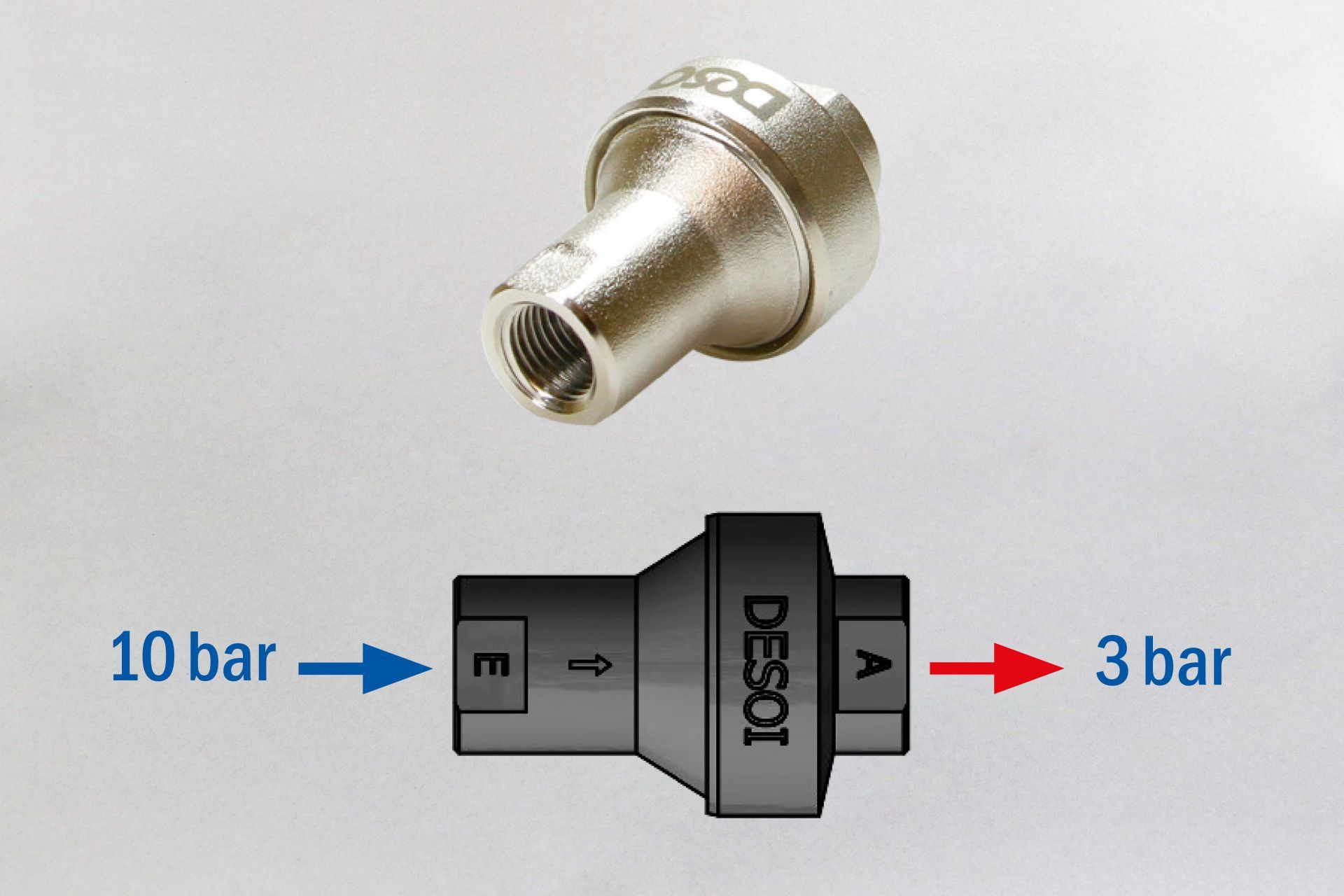

Accessory – Pressure limiter

The pressure limiter reduces the output pressure to 3 bar in order to protect the sealing elements of the core cooling system.

The core cooling with integrated temperature control tube is ideal for cooling thread cores, spindles, etc. Suitable temperature control agents are water and oils.

Accessory – Coolant filter

The very fine filter prevents the coolant from contamination. The filter element is easy to replace.

Add Item to

Shopping Basket

Add all selected Items

to Shopping Basket

Remove Item from Shopping Basket

Add item to favorites

Remove Item from Favorites

Stock Outage

Make a Preorder

Insufficient Stock

Item well stocked

Article in delivery

This item is part of a current campain