SELECT DISTINCT shop_view_active_item.*

FROM shop_item_has_category

INNER JOIN shop_view_active_item ON (

shop_view_active_item.company = shop_item_has_category.company AND

shop_view_active_item.shop_code = shop_item_has_category.shop_code AND

shop_view_active_item.language_code = shop_item_has_category.language_code AND

(

shop_item_has_category.item_no = shop_view_active_item.item_no

)

)

WHERE (shop_item_has_category.category_line_no = 115000)

AND shop_view_active_item.language_code = 'ENU'

AND shop_view_active_item.company = 'DESOI'

AND shop_view_active_item.shop_code = 'B2B'

AND shop_item_has_category.company = 'DESOI'

AND shop_item_has_category.shop_code = 'B2B'

AND shop_item_has_category.language_code = 'ENU'

AND shop_item_has_category.category_shop_code = 'B2B'

The entered access data are not correct. Please try again.

Become a customer

You do not have online access yet? Request your access data here.

Add Item to

Shopping Basket

Add all selected Items

to Shopping Basket

Remove Item from Shopping Basket

Add item to favorites

Remove Item from Favorites

Stock Outage

Make a Preorder

Insufficient Stock

Item well stocked

Article in delivery

This item is part of a current campain

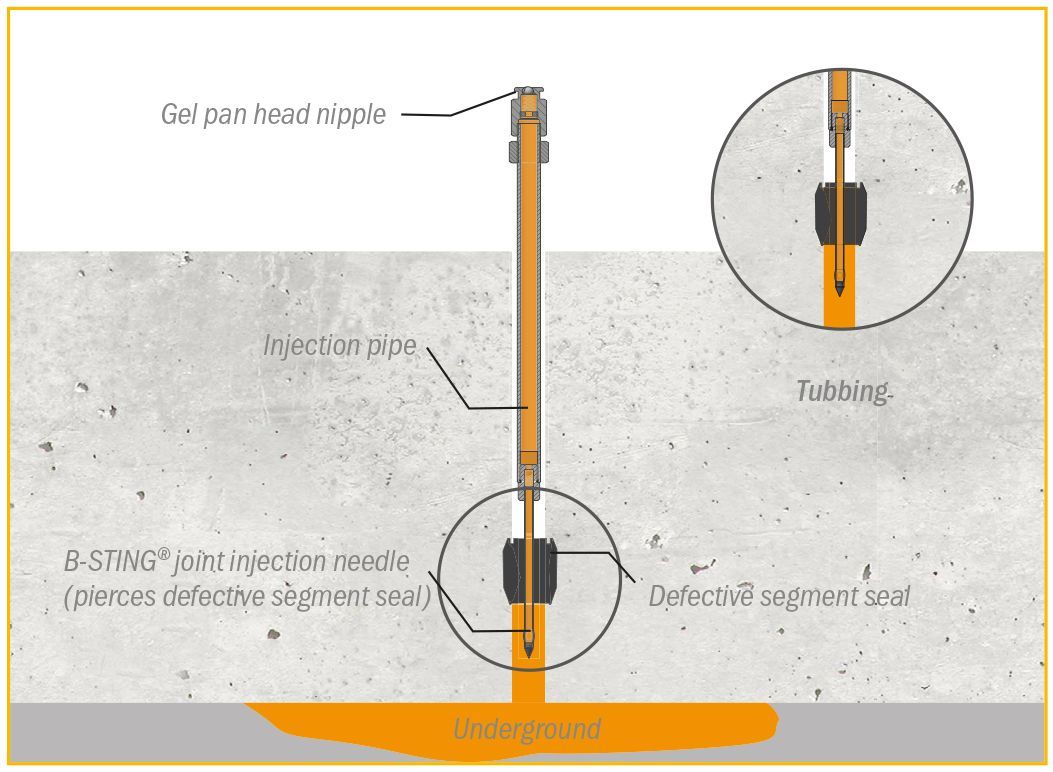

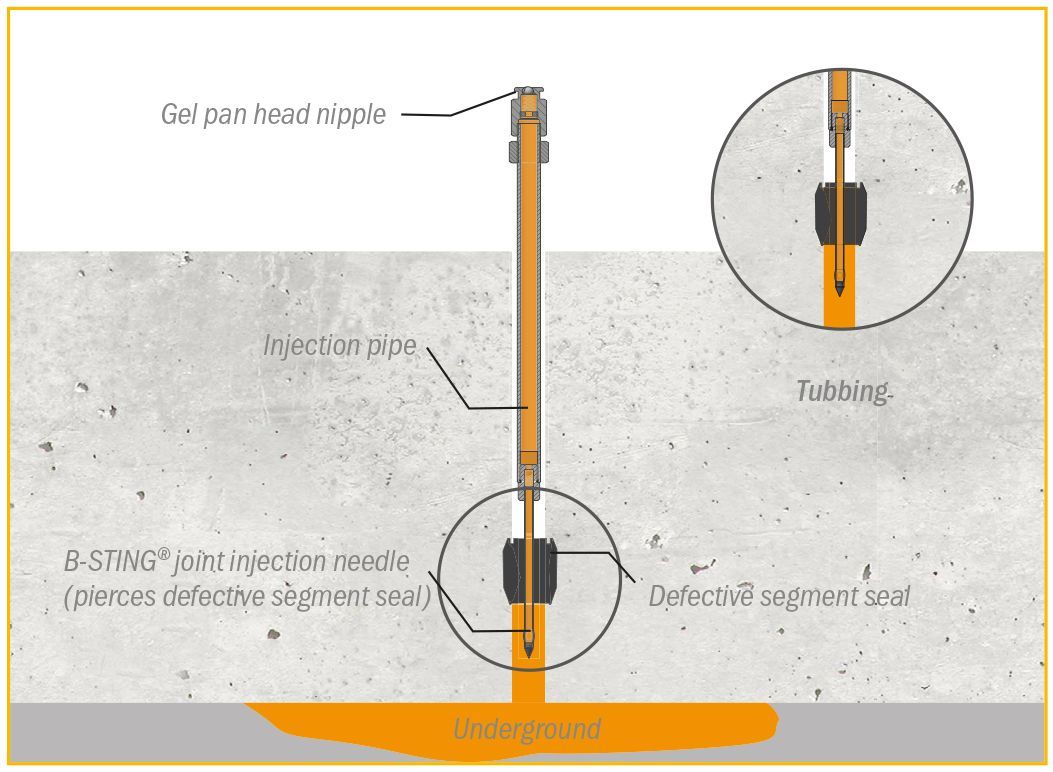

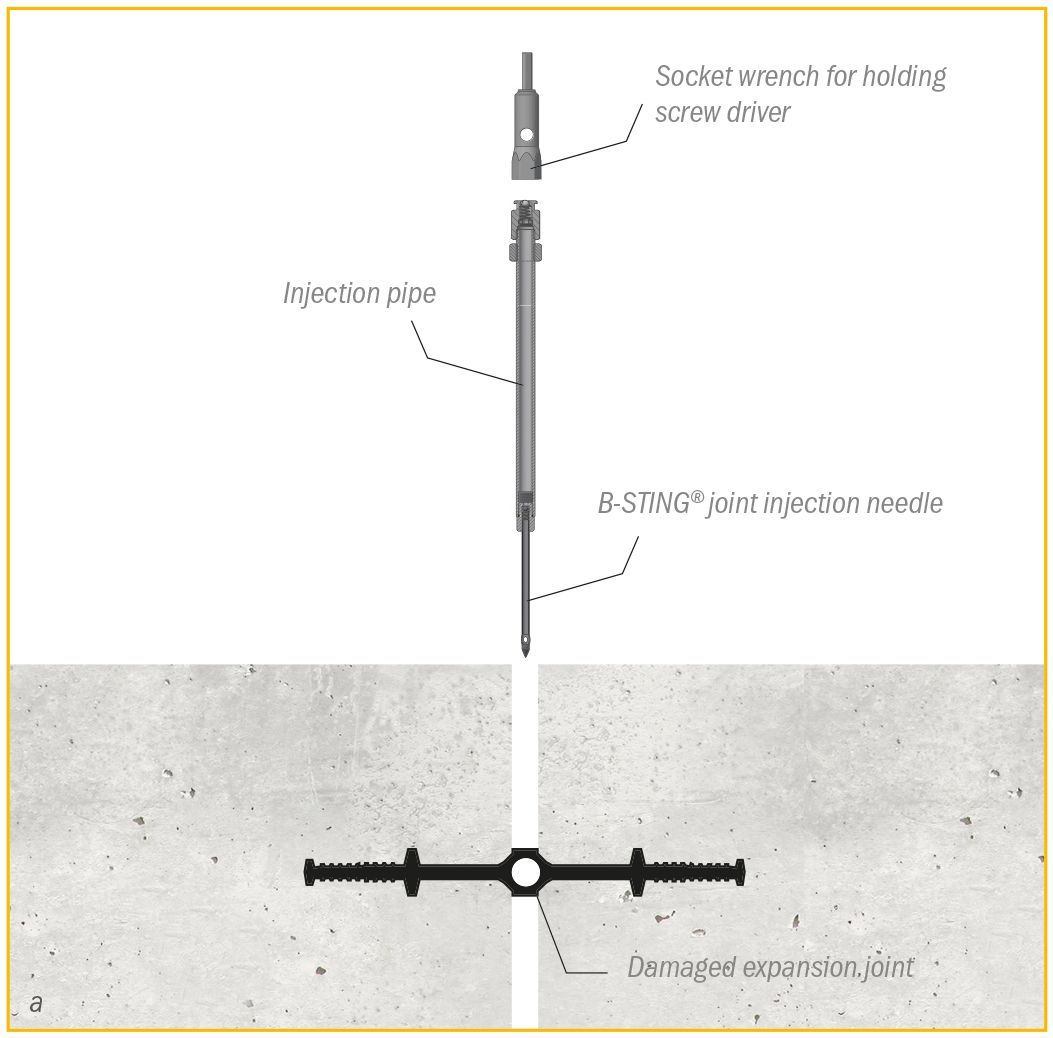

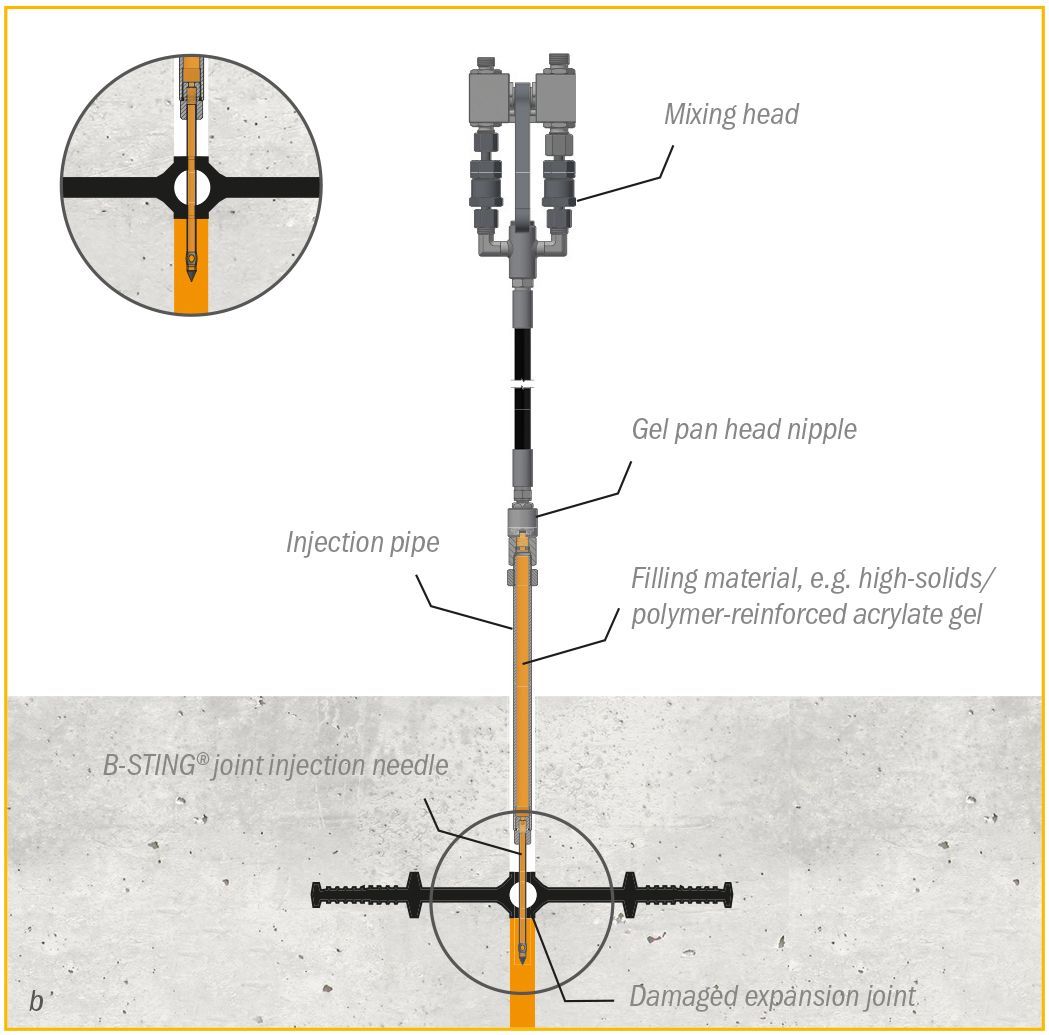

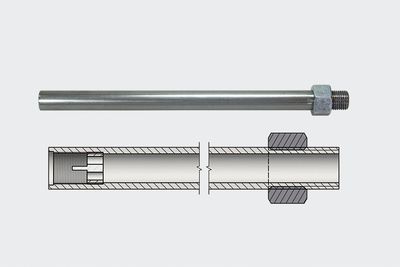

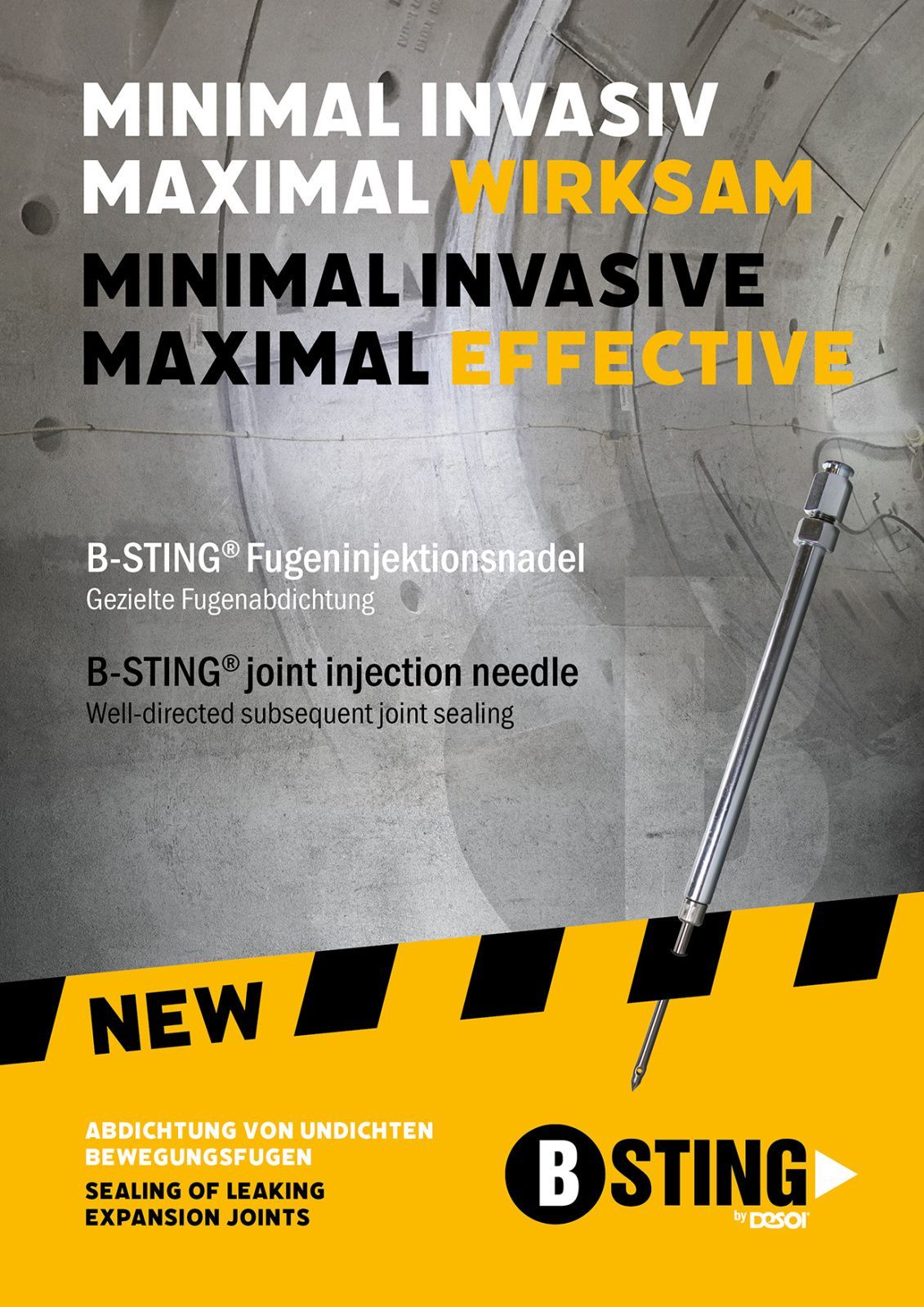

B-STING® joint injection needle

The B-STING® joint injection needle enables simple and safe sealing of sealing joints in tunnels, especially in segmental tunnels. The joint is sealed by screwing in the B-STING® with a cordless screwdriver and injecting an acrylate or polyurethane-based filler. The B-STING® remains in the component and ensures a permanent seal. There is no need for time-consuming drilling work during application.

NEW is the use of the B-STING® joint injection needle for sealing leaking expansion joints.

B-STING® joint injection needle

open PDF

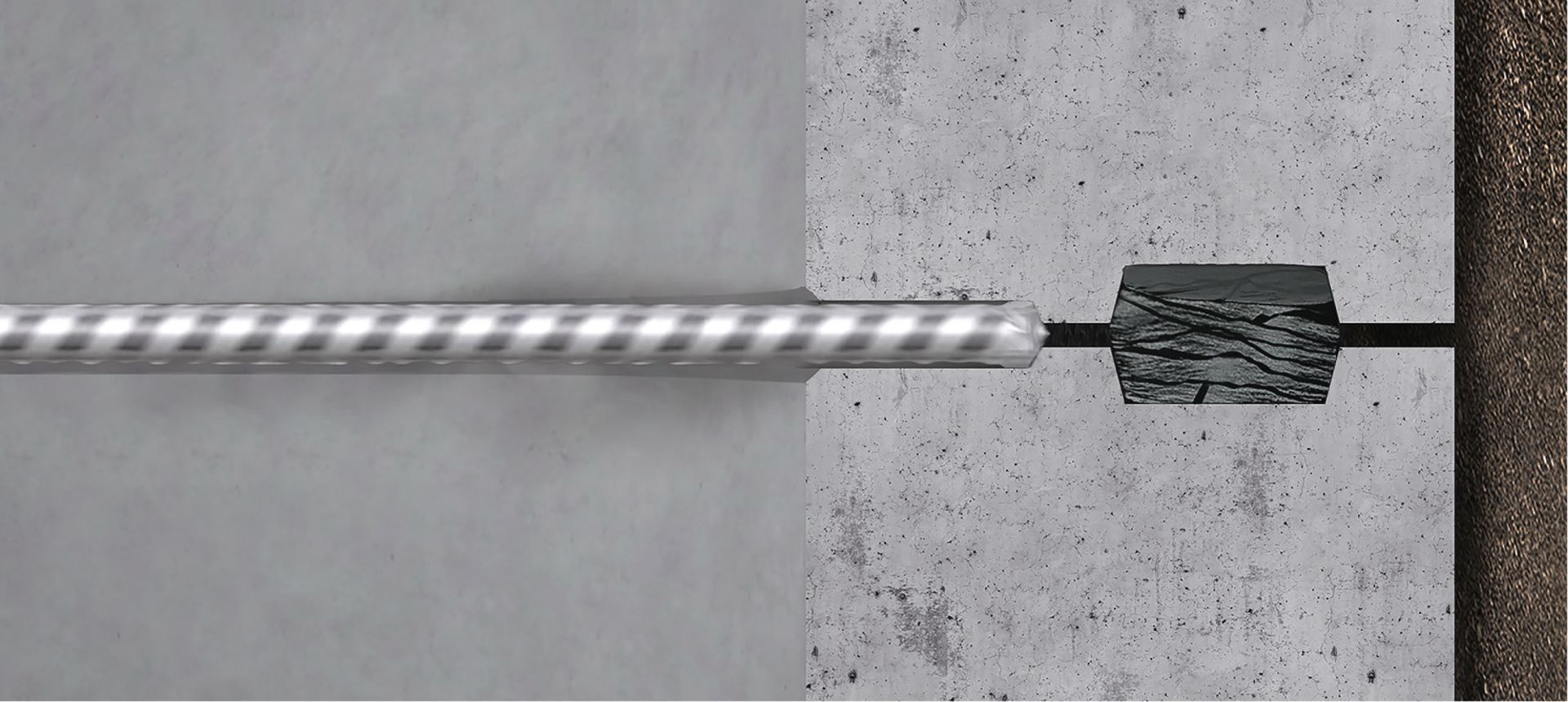

Minimal invasivE - maximal EFFECTIVE

advantages

advantages

- No drilling through reinforced concrete

- The B-STING®® joint injection needle penetrates the sealing element without removing any material

- No material removal => no leaks

Materials used

Materials used

- Acrylate gel

- Injection resin

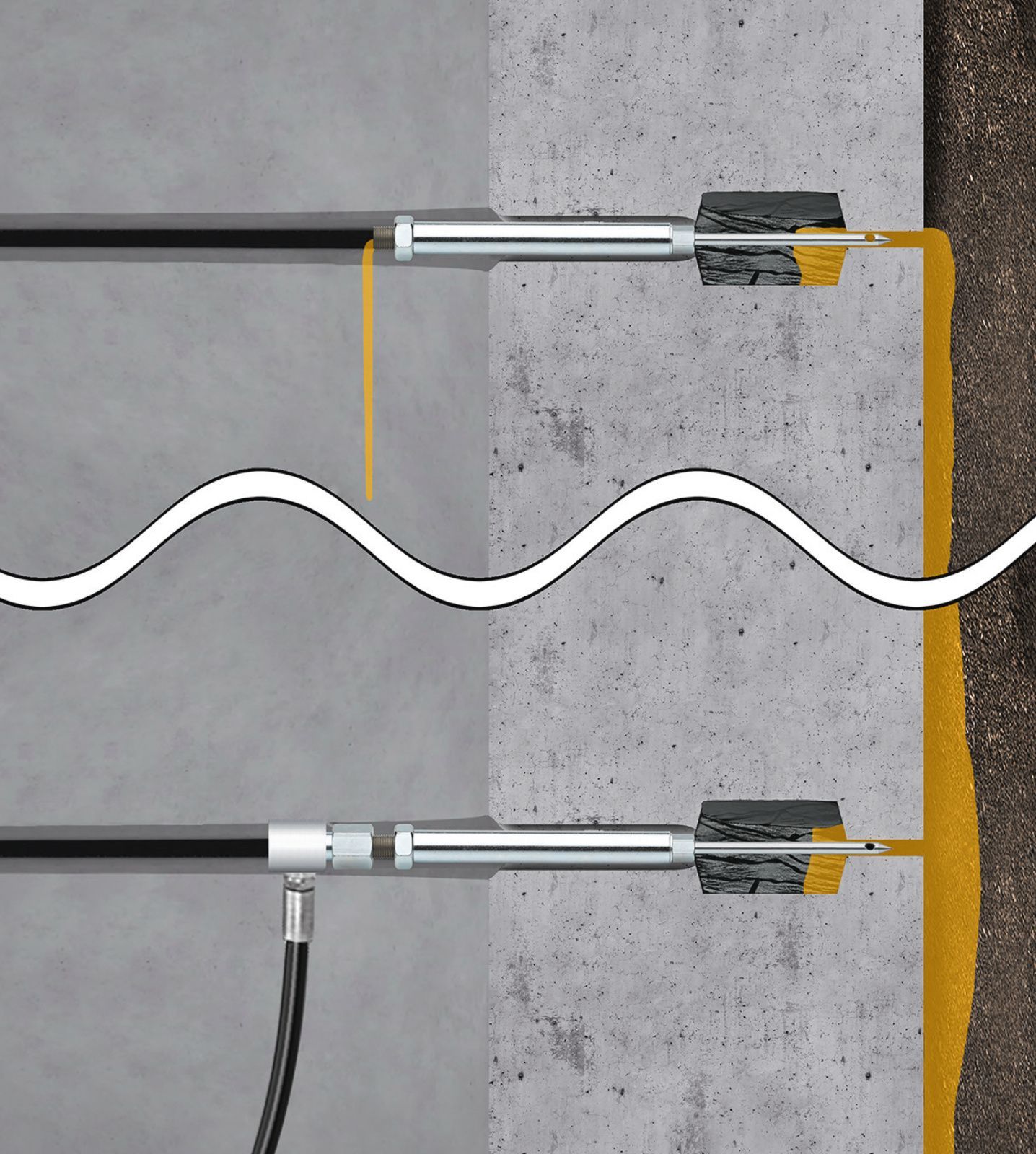

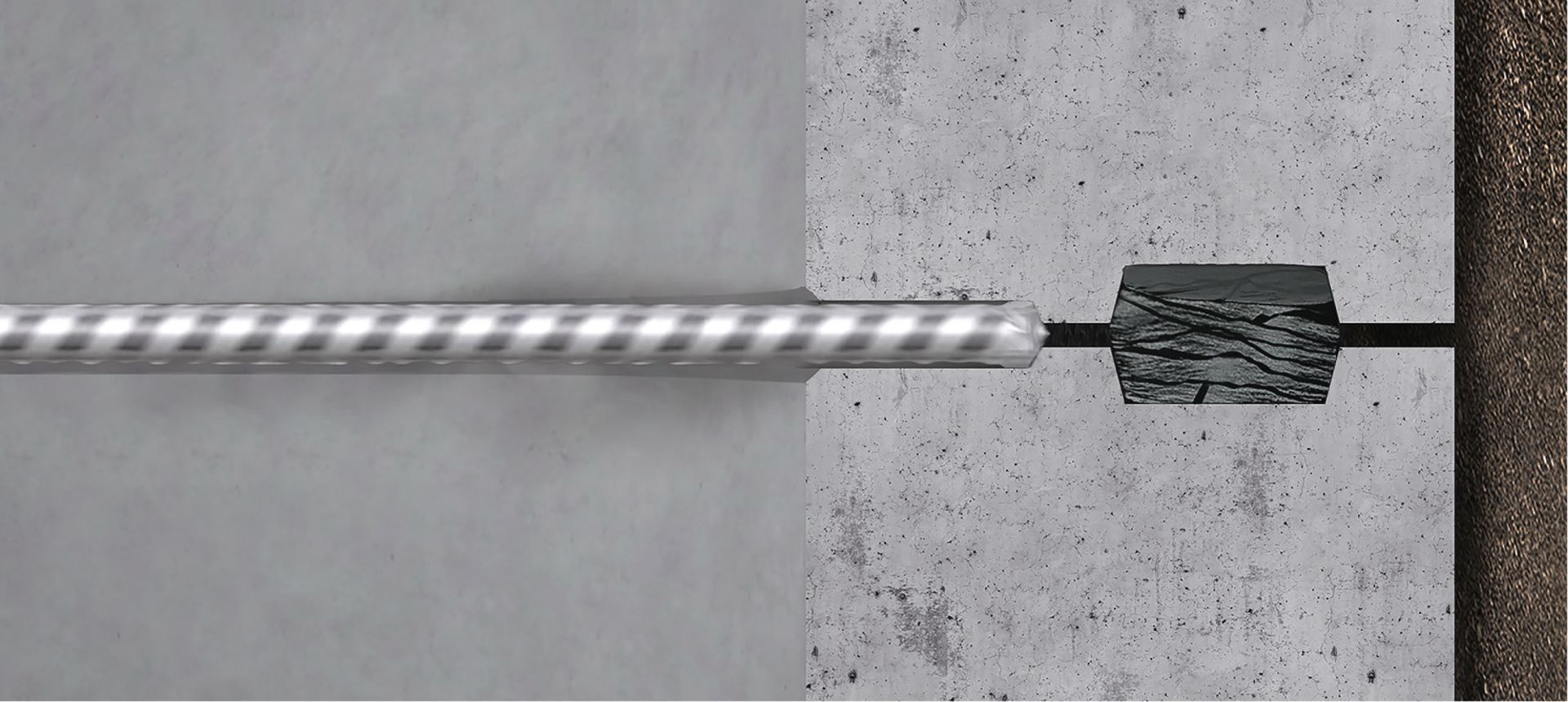

Sealing of leaking

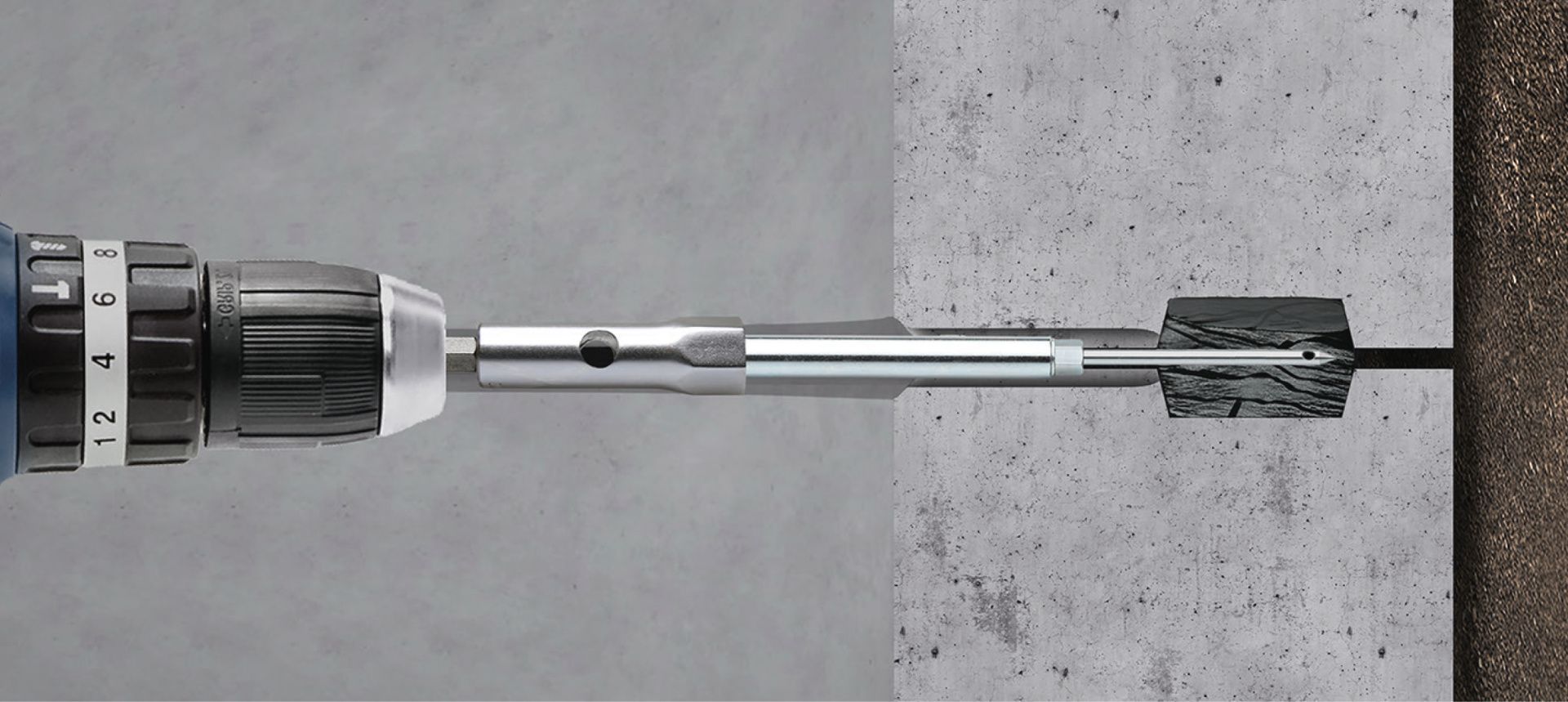

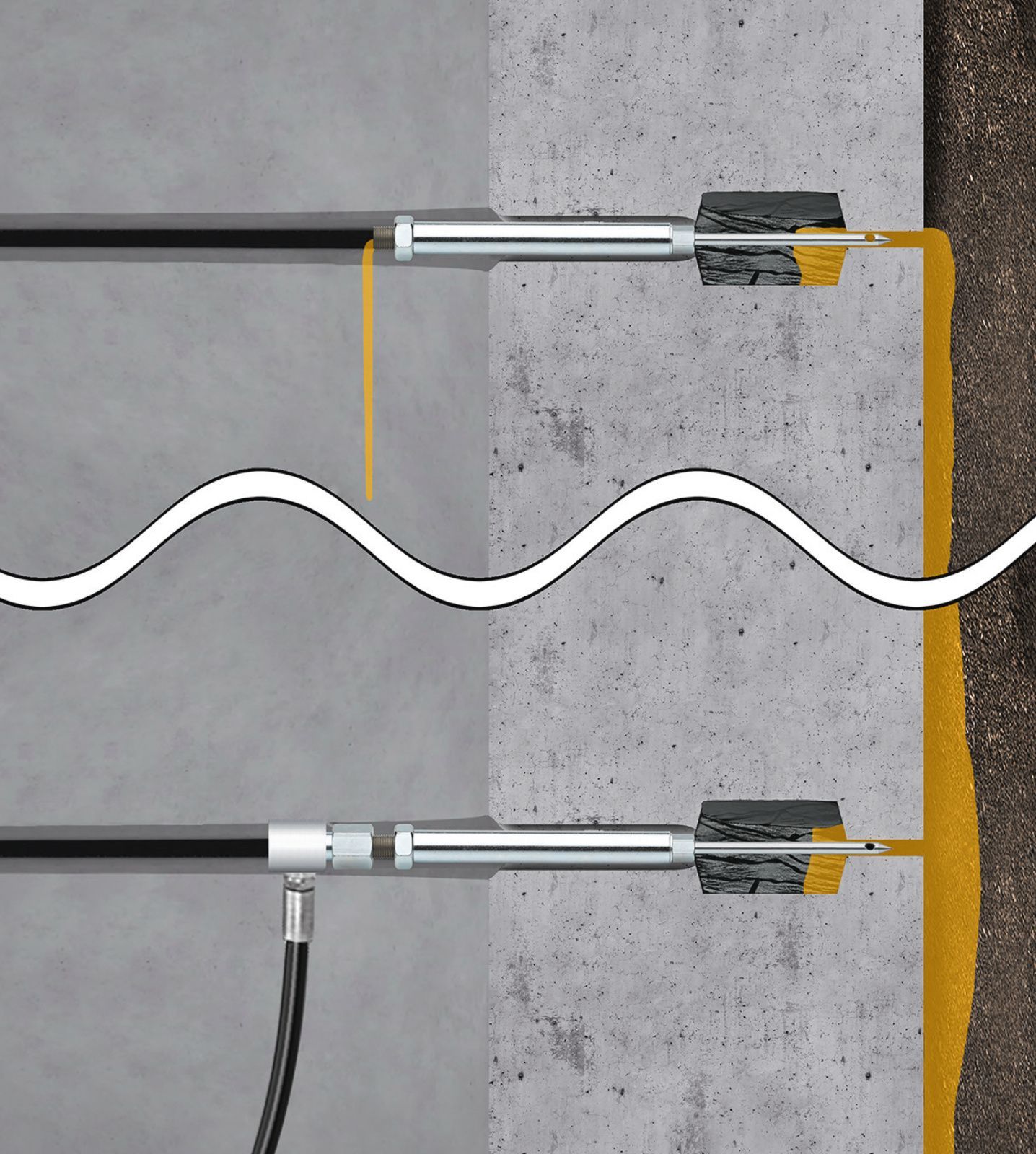

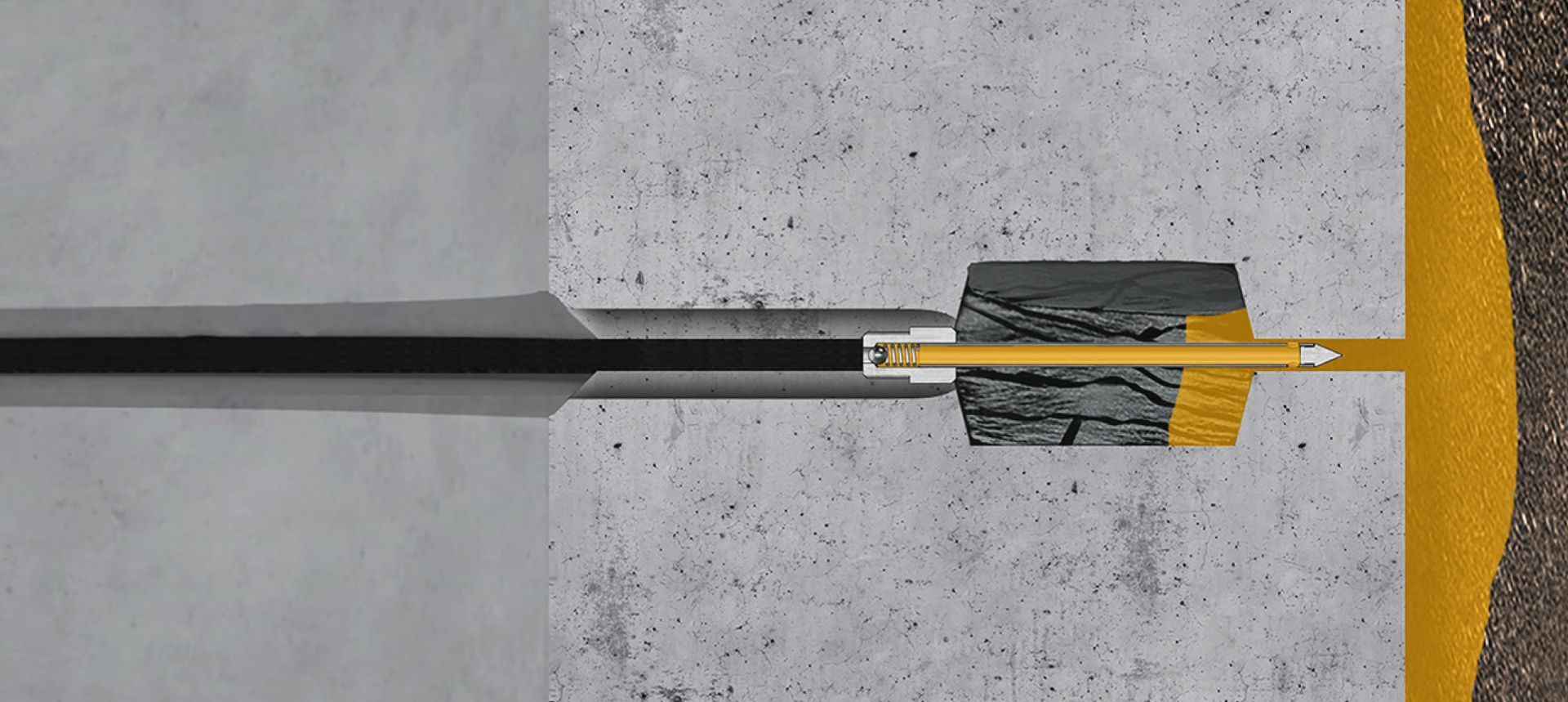

Segment joints

The procedure is basically identical for the subsequent sealing of segments. In this method, an approximately 5 mm thick joint injection needle is screwed into the segment seal via the segment joint using a cordless screwdriver and penetrates the segment seal. An acrylate or polyurethane-based fi ller is injected into the segment joint via a fl at-head gel nipple and the injection tube screwed onto the B-STING®. However, due to the smaller joint width, it is usually necessary to drill out the longitudinal or annular joints of the segments in order to be able to insert the injection pipe with the B-STING® joint injection needle into the joint. As a rule, a drill hole with a diameter of approx. 18 mm is su cient for this. The B-STING® joint injection needle remains in the segment seal and seals the hole permanently.

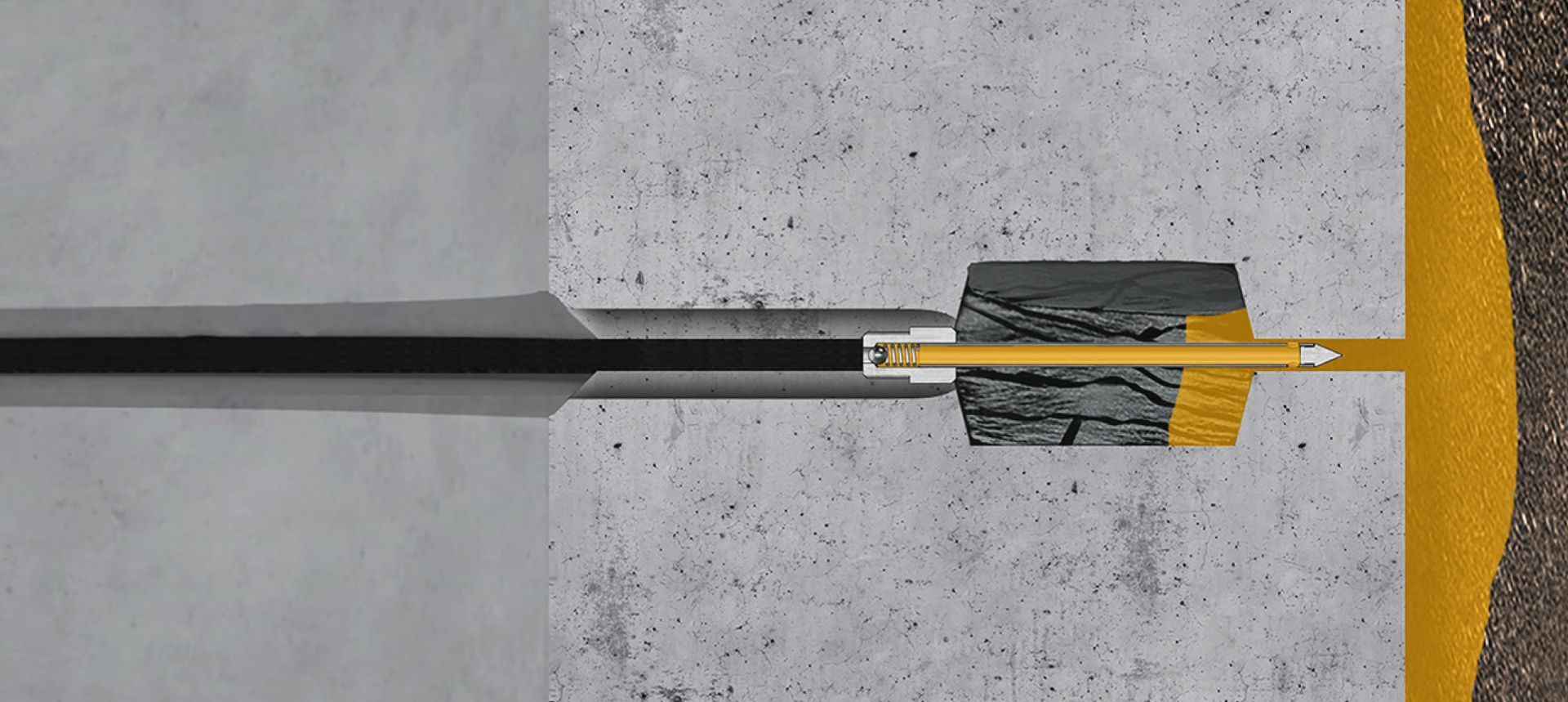

Sealing the joint in the case of a leaking segment joint using a B-STING

® joint injection needle

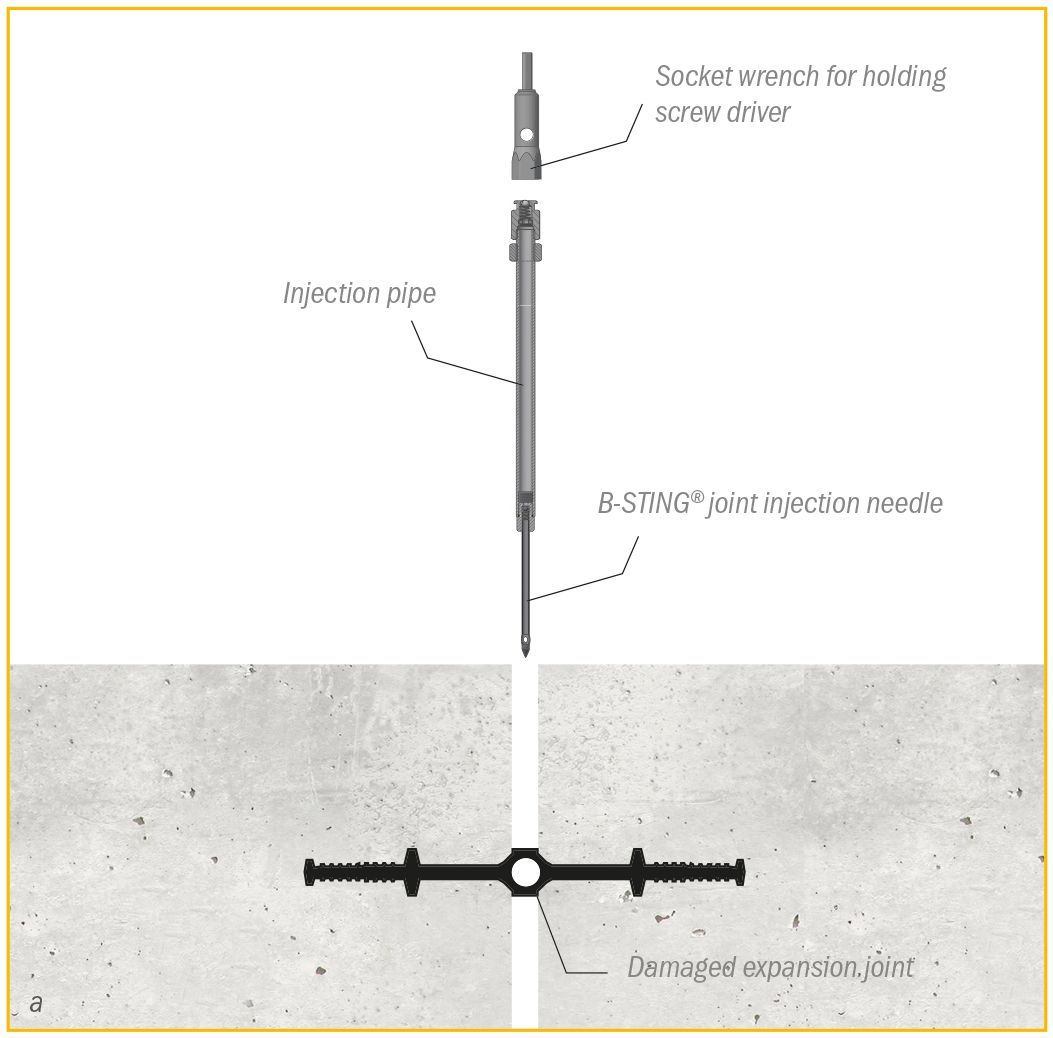

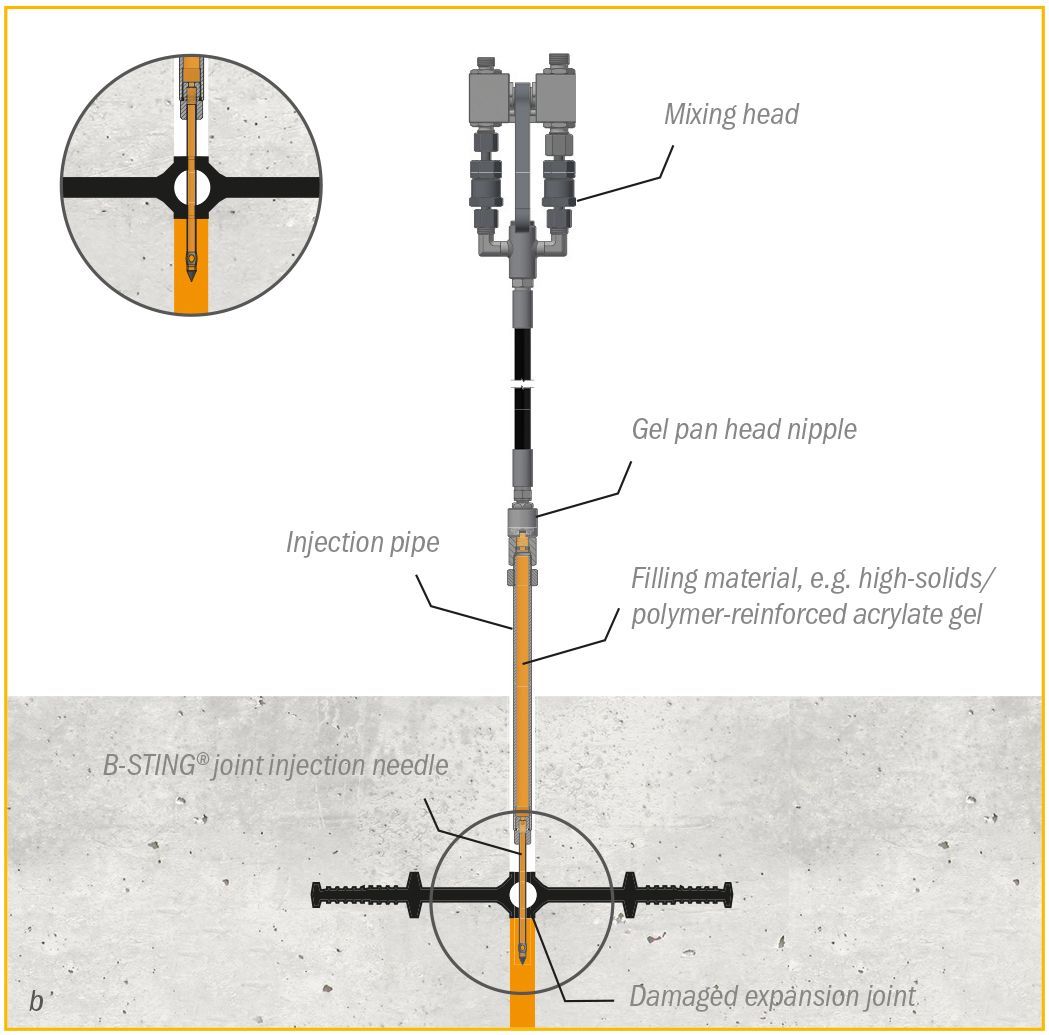

Sealing of leaking

Expansion joints

In this process, the B-STING® joint injection needle is screwed into the expansion joint through the sealing element using a cordless screwdriver. Injection is carried out into the water-facing side of the joint via a fl at-head gel nipple and the injection pipe screwed onto the B-STING®. After the injection process, the injection pipe is removed while the B-STING® remains in the seal and seals the injection

point permanently and water pressure-tight.

a) Positioning the B-STING

® joint injection needle

b) Injection

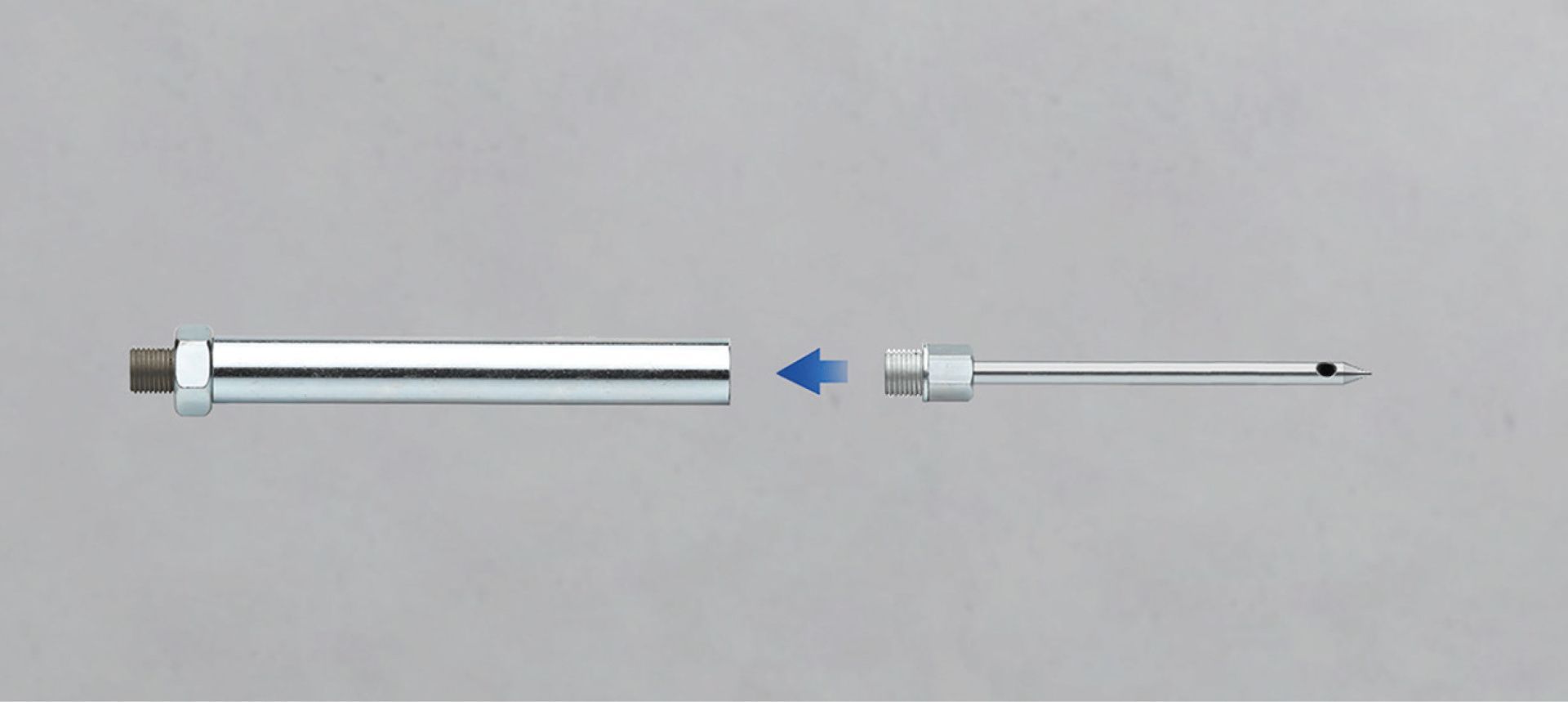

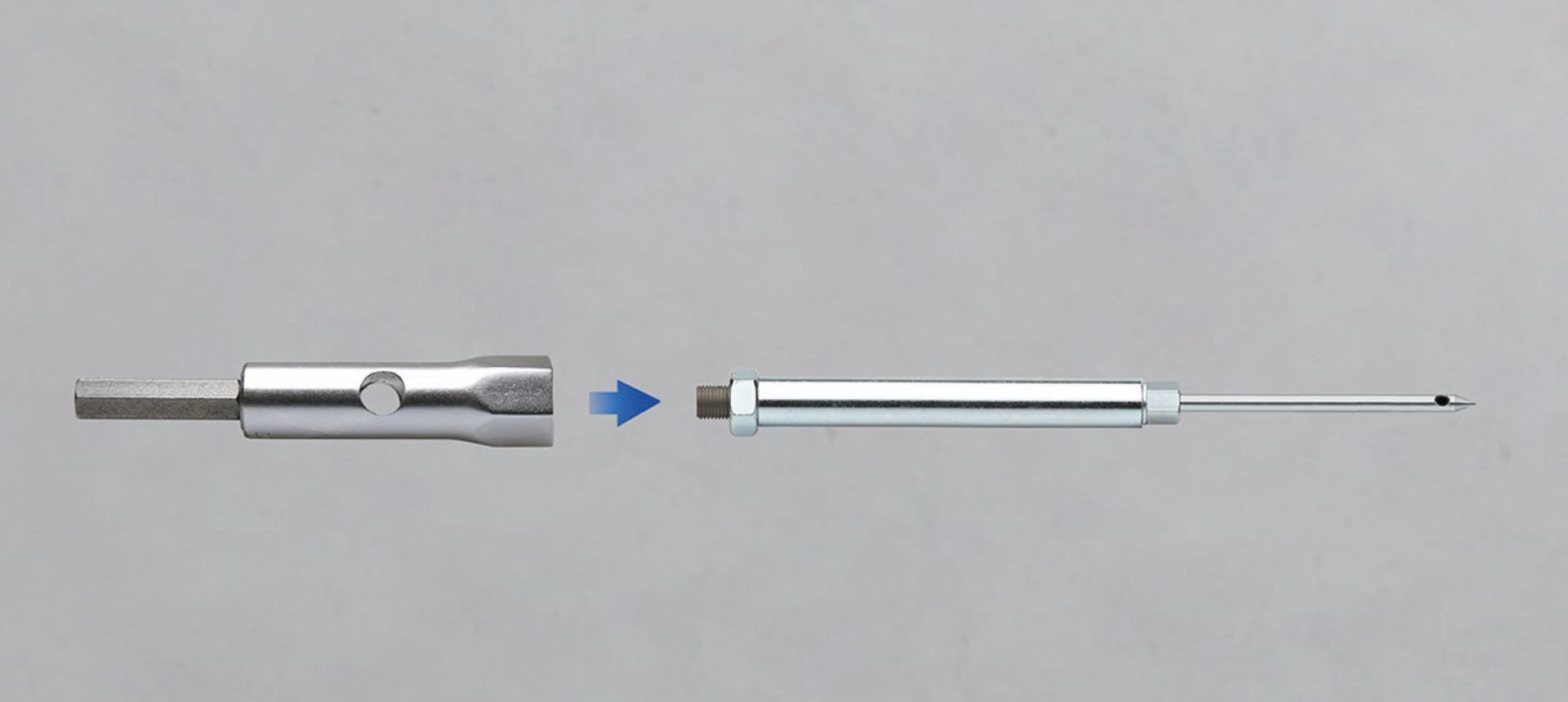

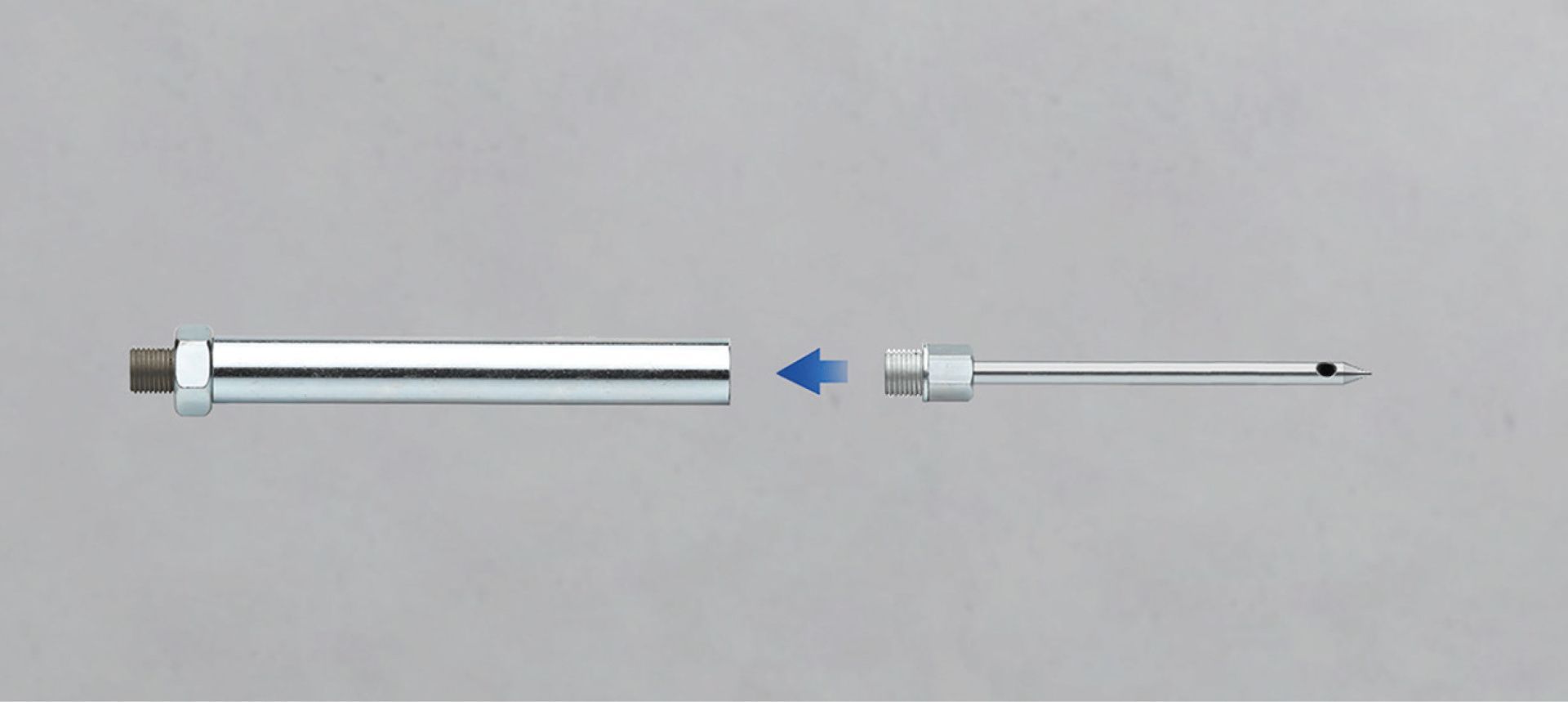

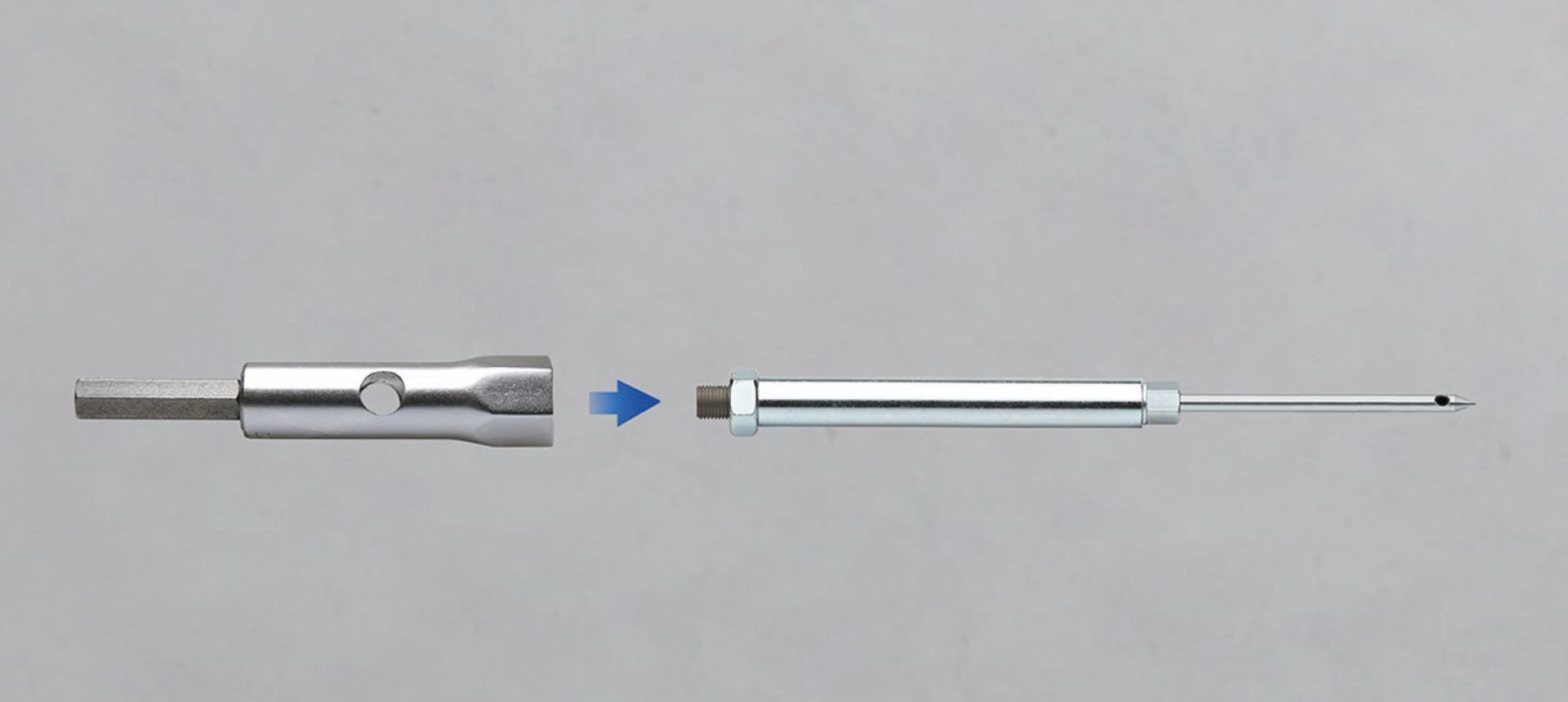

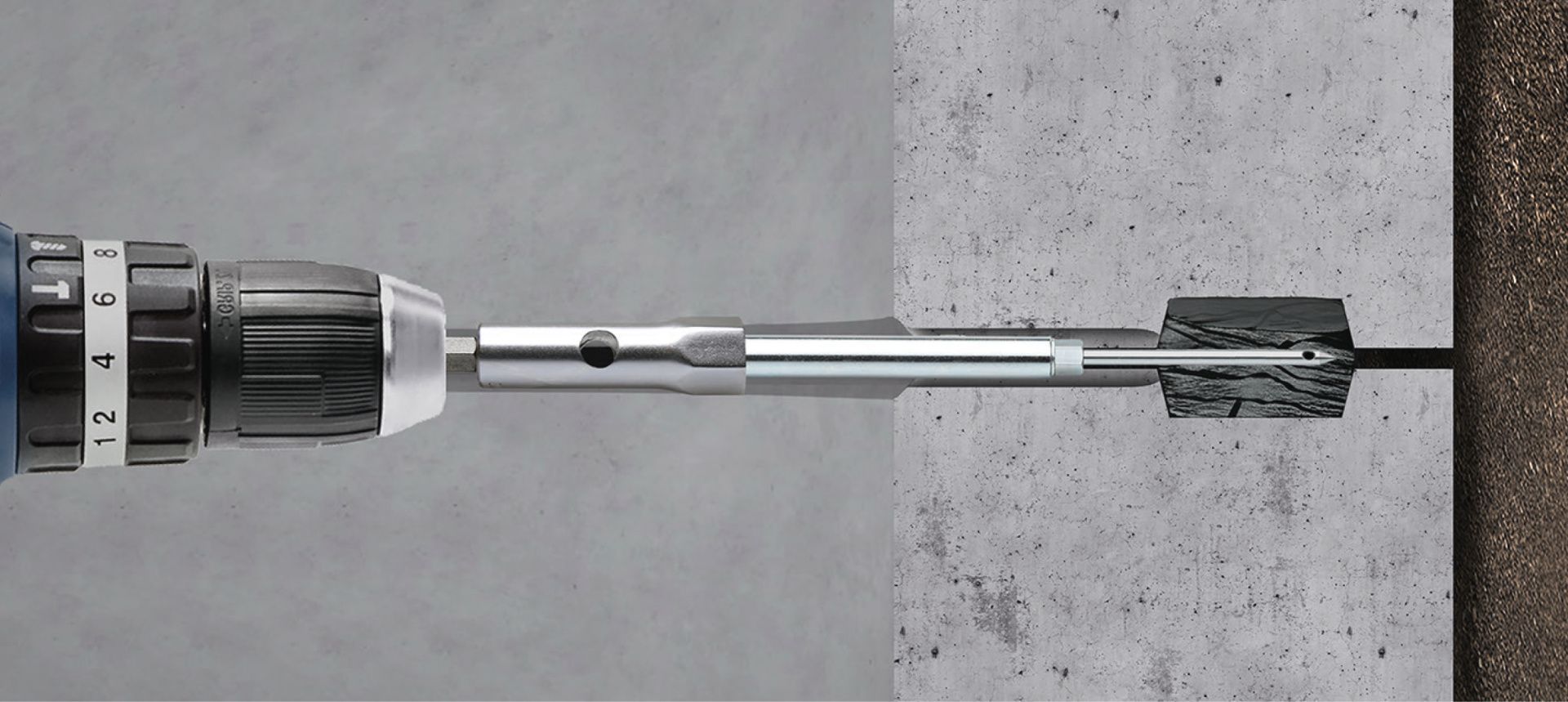

WORKING STEPS

WORKING STEPS

➀

Drill down to the sealing element (This does not apply to expansion joints).

➁

Installing the injection pipe

➂

Fit socket wrench

➃

Screw in with a cordless screwdriver

➄

Inject

➅

Inject until fi ller emerges from the next B-STING® joint injection needle

➆

Completed injection, B-STING® joint injection needle remains in the component

Mehr Informationen

Externe Medien Akzeptieren

Wir brauchen Ihr Einverständnis!

Wir benutzen Drittanbieter, um Videoinhalte einzubinden. Diese können persönliche Daten über Ihre Aktivitäten sammeln. Bitte beachten Sie die Details und geben Sie Ihre Einwilligung.

Mehr Informationen

Externe Medien Akzeptieren

advantages

advantages