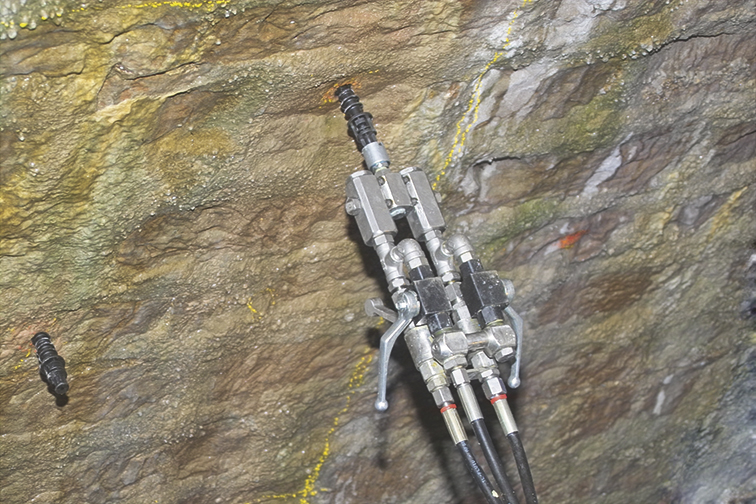

Curtain injection

More InformationsFilter

4 Variants

2 Variants

5 Variants

5 Variants

3 Variants

2 Variants

5 Variants

2 Variants

3 Variants

2 Variants

5 Variants

4 Variants

2 Variants

8 Variants

9 Variants

2 Variants

7 Variants

7 Variants

4 Variants

Curtain injection

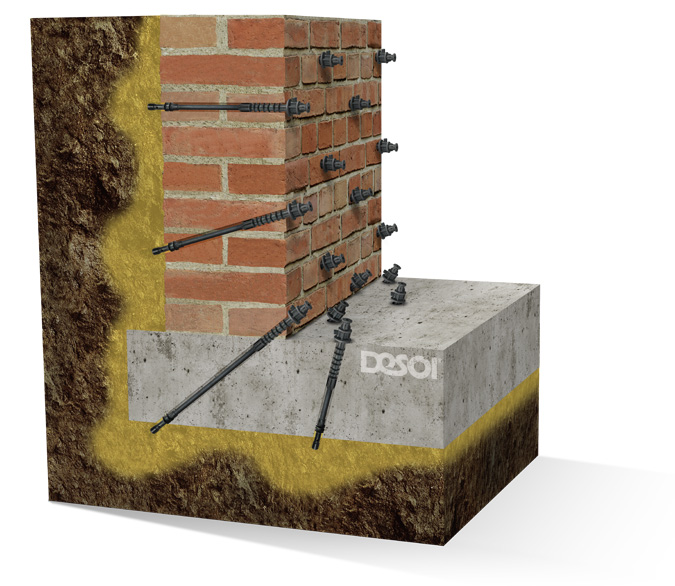

Sealing by gelation, e. g. curtain or surface injection, is a highly effective alternative for the subsequent sealing of engineering and traffic structures as well as for buildings in building and residential construction. A prerequisite for successful subsequent sealing is knowledge of the cause of the moisture damage that has occurred.

Application aim

- Sealing of structures in contact with the ground or inundated with the ground from the inside out

- Subsequent sealing of element walls

- Filling of cavities and cracks (special proof of suitability required)

- Subsequent sealing of leaking expansion joints

- Subsequent injection of expansion joints between joint tape and water-resistant component surface

Filling material

- Acrylate gel

Demands on the injection packers

- Safe retention in the structural element during the injection at pressures depending on the injection method

- Corrosion resistance of elements remaining in the structural element

- Shut off option

- Cross section adjusted to the required delivery and flow properties of the injection material

- Check valves for low opening pressure

Demands on injection devices

- Forced delivery of the components at reliably adjustable mixing ratios

- Powerful mixing head with check valves and cut off cocks

- Mixing line suitable for the injection material

- Separate high-pressure rinsing pump

- Monitoring and documentation of injection and dosing processes - DESOI w.i.l.m.a., (please request consultation and brochure!)

Suitable objects

- Houses and industrial structures

- Civil engineering structures

- Civil and canal construction

- Water engineering

- Tunnelling

Types of packers

- Bore packers (steel)

- Drive-in packers (polymer)

Fields of application

- The untight building component is drilled through from the inside to the outside

- The low-viscosity, liquid injection material displaces the existing water and forms an elastic sealing layer and / or an elastic injection body, together with the surrounding building ground

Information on the injection methods

- Injections into the building ground are subject to compulsory notification according to art. § 49 of the Water Resources Act (German abbreviation WHG)

- Prior to starting any gel injection work, a corresponding notification should be submitted to the competent Lower Water Authority and the Agency for Environmental Protection

- Construction chemical products should be accompanied by a suitability certificate according to the principles of the evaluation by the German Institute for Building Technology (German abbreviation DIBt)

- An expert engineer (competent planner) should be appointed with the planning

Injection of expansion joints

- Leaky expansion joints are usually sealed by partial curtain injection

- Leaky construction joints are treated like cracks with regard to injections

Support measures

- Provision of technical advice and recommendations with regard to competent planners and specialists for the execution of the work involved

- DESOI recommendation; technical specifications

- DESOI ABC of injection: The reference work for construction experts

- DESOI technical brochure: Sealing with injection methods

- WTA information sheet; gel injection 5 – 20

- STUVA ABI information sheet (edition 2014)

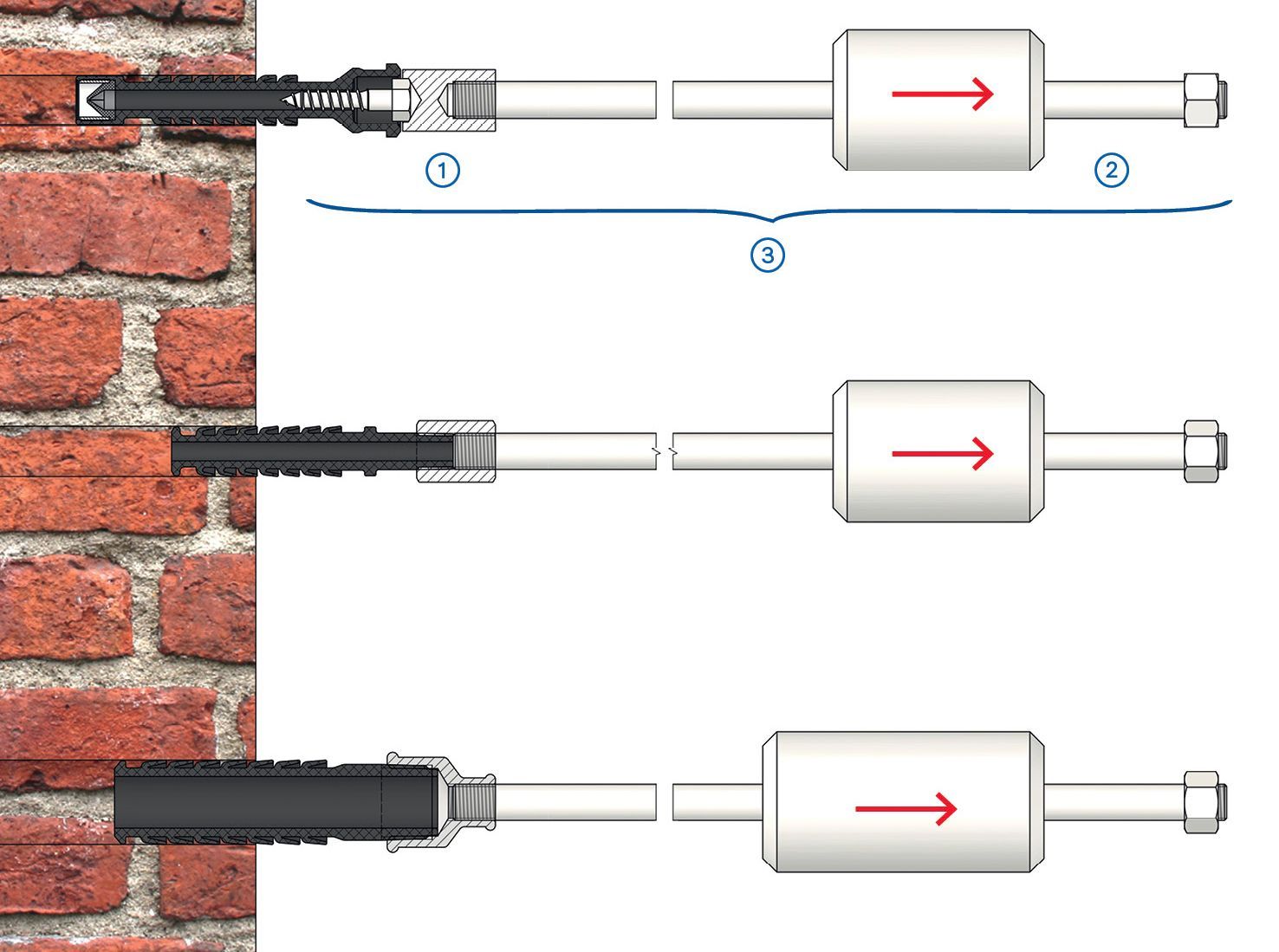

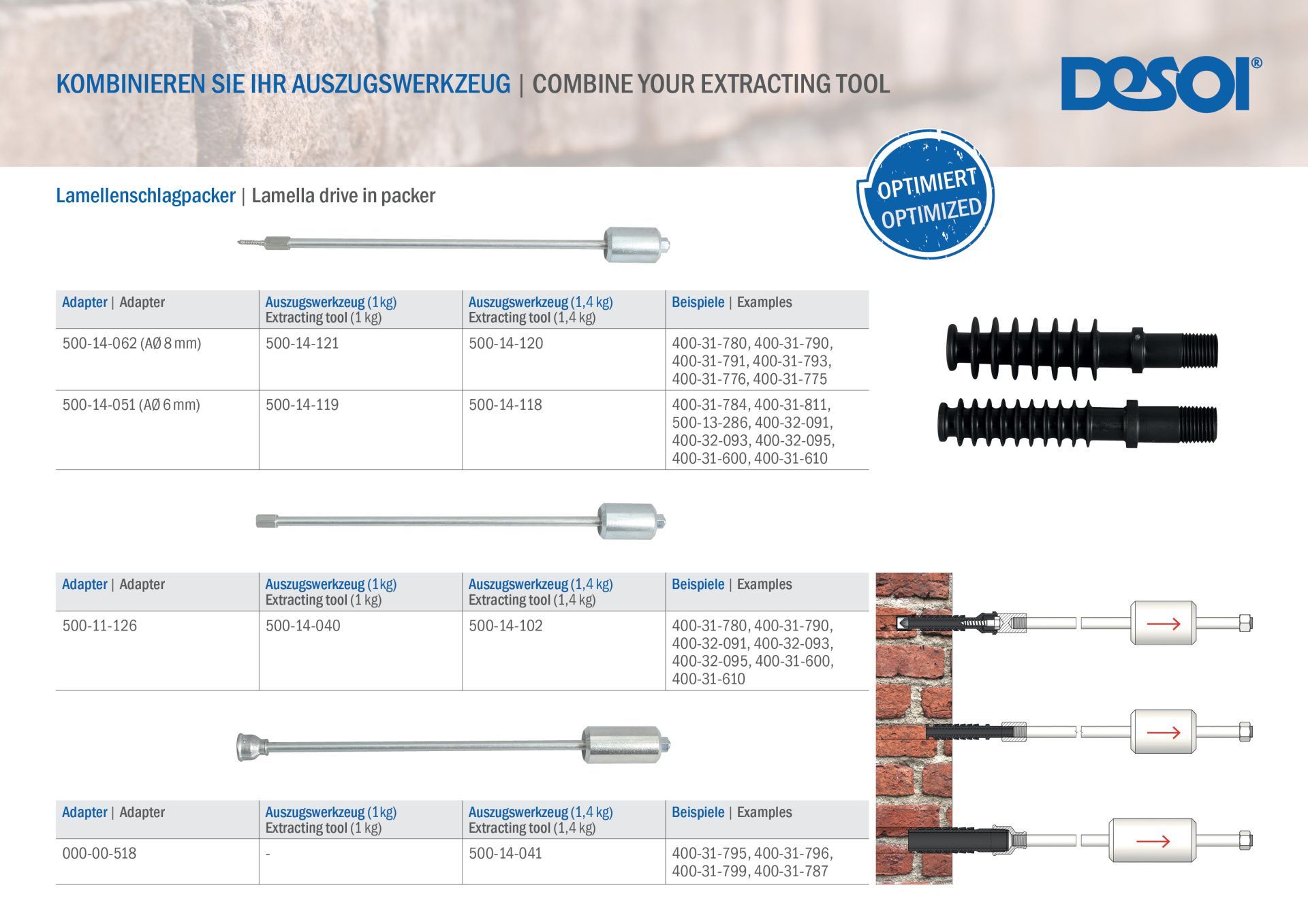

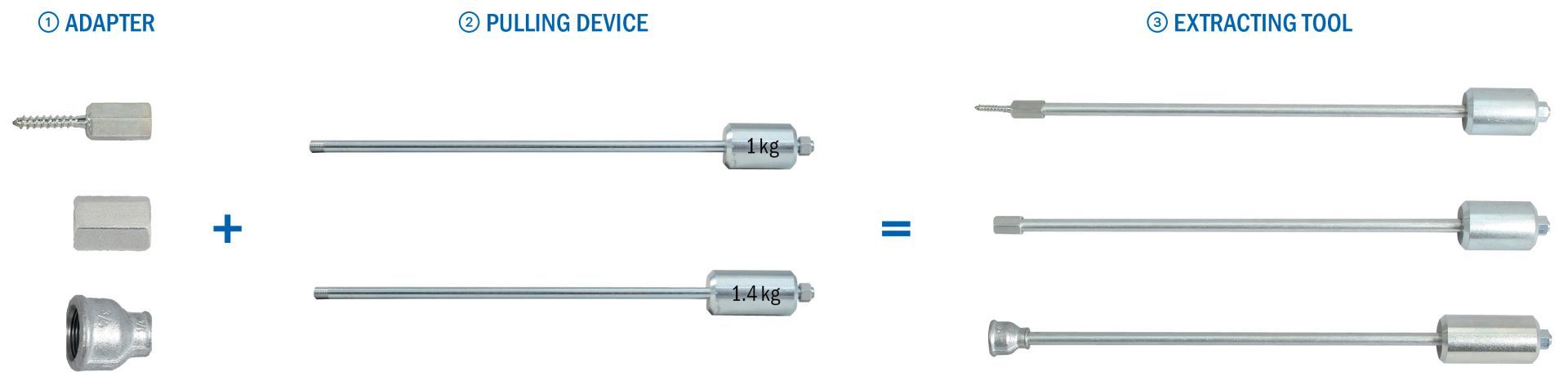

Extracting tool for lamella drive-in packer

Combine your extracting tool

In order to remove lamella drive-in packers from the construction element there are different extracting tools available, varying to the type of the packers. The extracting tool is screwed in or on the lamella drive-in packer and the impact weight is moved powerful into the pull-out direction. Step by step the packer is removed from the construction element.- Basis: Pull rod

- Weights available individually between 1 kg and 1.4 kg

Advantages

- For the extraction of different types of packers

- All adaptors can be combined with both pulling devices according to the application

- Reusable product

- Easy handling

Extracting tool

Application