Masonry injection

More InformationsFilter

3 Variants

16 Variants

6 Variants

21 Variants

47 Variants

2 Variants

2 Variants

4 Variants

3 Variants

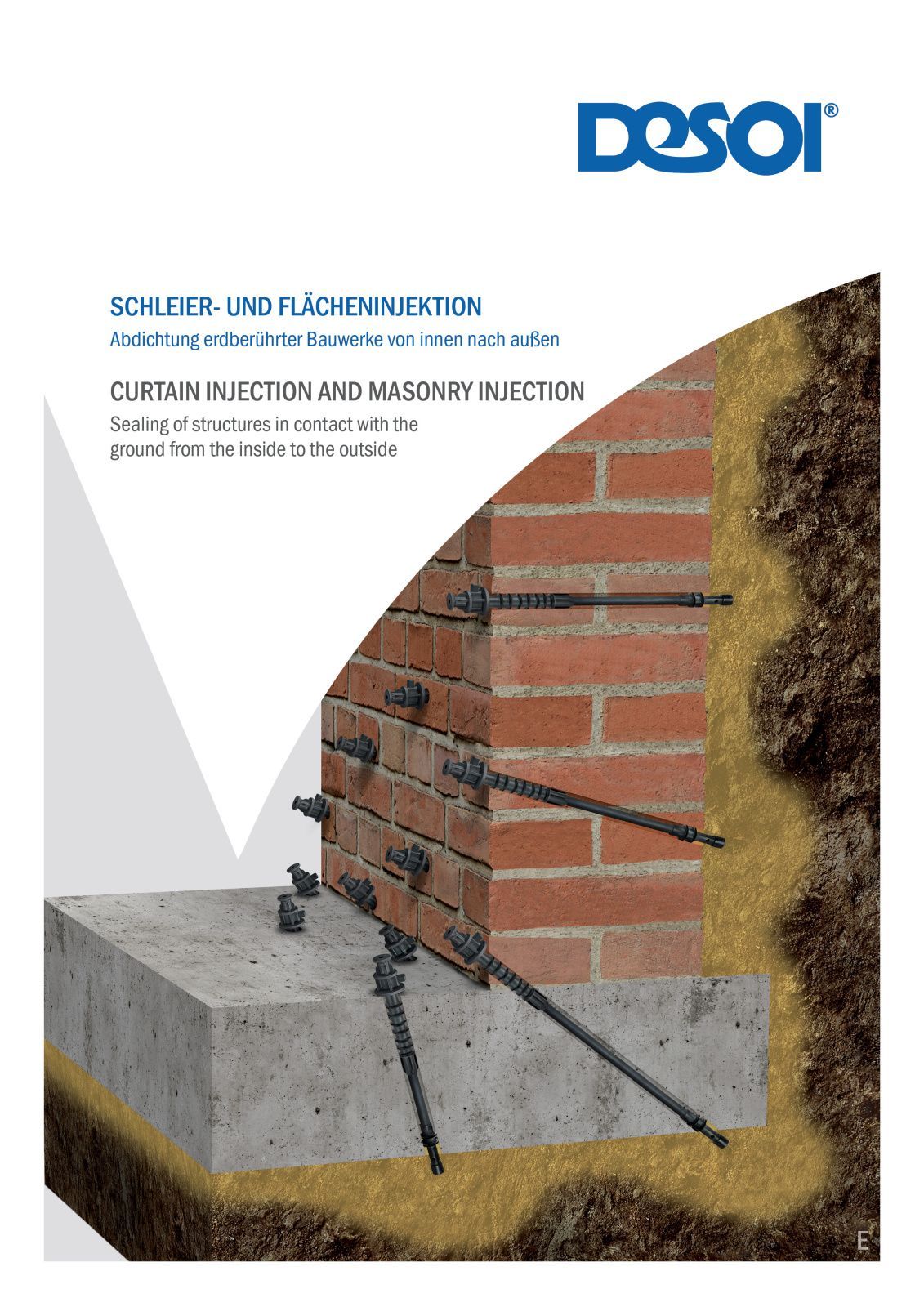

Masonry injection

With the masonry injection leaking structural elements covered with earth can subsequently be sealed from the inside. Depending on the building material composition and pore structure, a continuous sealing layer in the structural element (masonry) is created. By injecting suitable materials such as low-viscosity gels or resins, the water transporting capillaries are sealed.

Application aim

- Sealing of structures in contact with the ground or inundated with the ground from the inside out

- Subsequent sealing of element walls

- Filling of cavities and cracks (special proof of suitability required)

- Subsequent sealing of leaking expansion joints

- Subsequent injection of expansion joints between joint tape and water-resistant component surface

Filling material

- Acrylate gel

Demands on the injection packers

- Safe retention in the structural element during the injection at pressures depending on the injection method

- Corrosion resistance of elements remaining in the structural element

- Absperrmöglichkeit

- Shut off option

- Cross section adjusted to the required delivery and flow properties of the injection material

- Check valves for low opening pressure

Demands on injection devices

- Forced delivery of the components at reliably adjustable mixing ratios

- Powerful mixing head with check valves and cut off cocks

- Mixing line suitable for the injection material

- Separate high-pressure rinsing pump

- Measurement technology for monitoring and documentation of injection and dosing processes - DESOI Flow Control II, (please request consultation and brochure!)

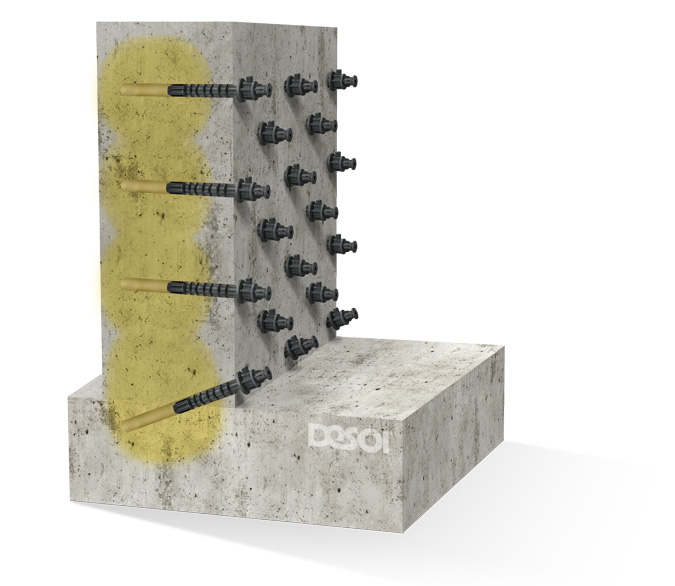

Masonry injection in the building component

- The sealing layer is created in structural parts which initially have not been planned to be sealed

- The water transporting capillaries are sealed

Masonry injection in cavities

- The sealing layer is created in technologically conditioned parting planes, e. g. in cavities between double walls

Crack injection and injection of hollows

- Very often partial crack injections and injections of limited hollows have to be carried out, e. g. raster injection

Procedure

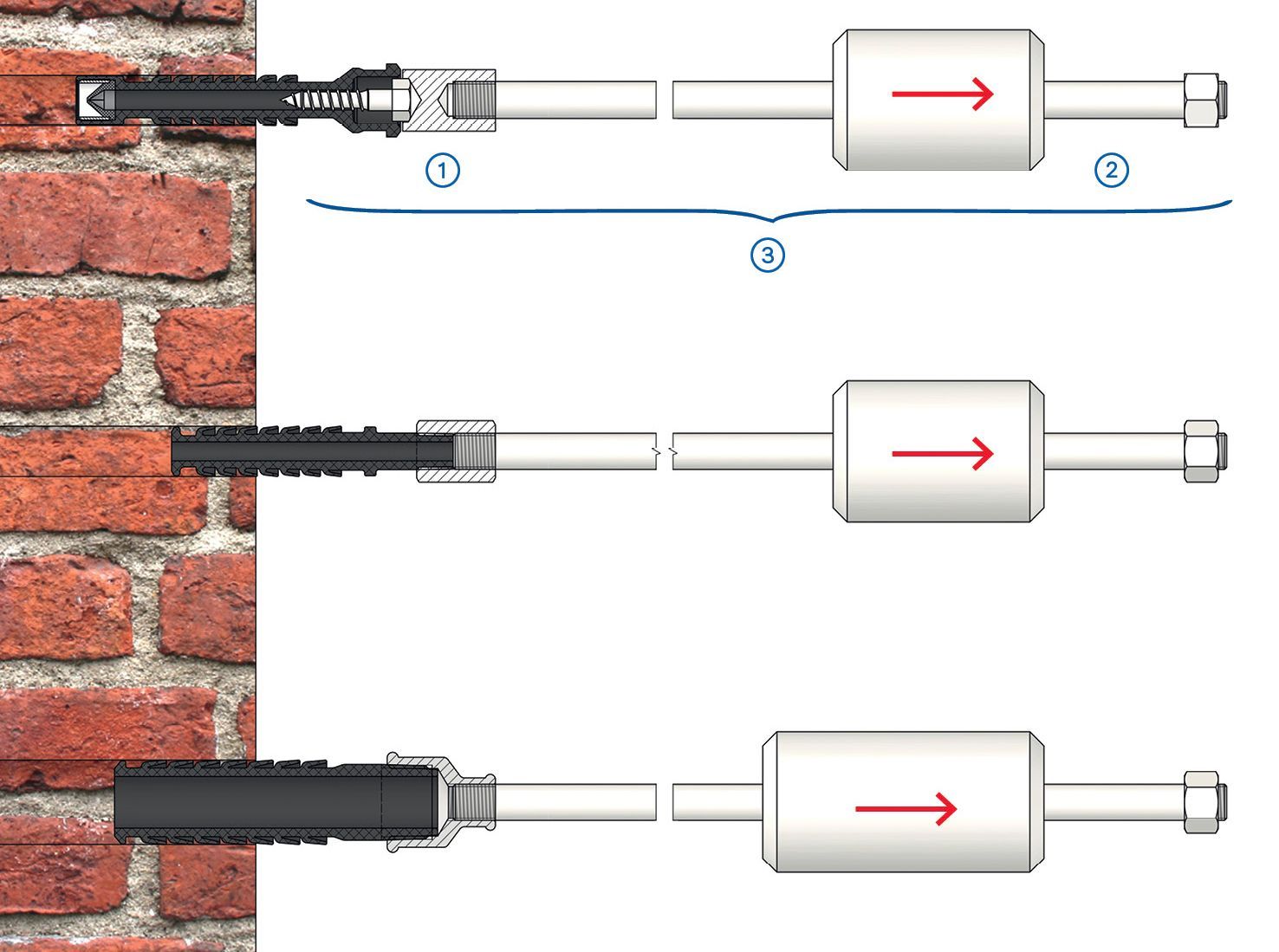

- Boreholes are drilled into the leaking structural element from the inside to the outside, up to approx. of the thickness of the structural element, at a slight angle of inclination

- The borehole pattern depends on the geometry of the structure

- The packers through which the injection material is injected are placed in the boreholes

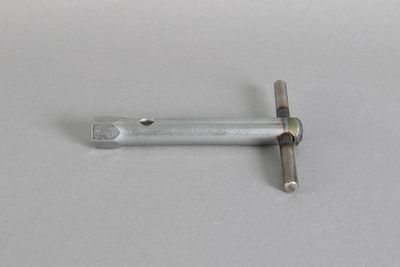

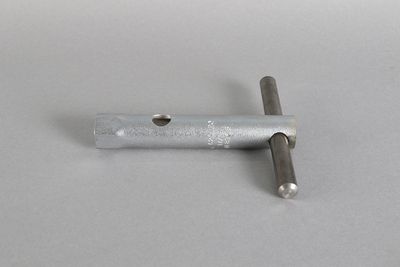

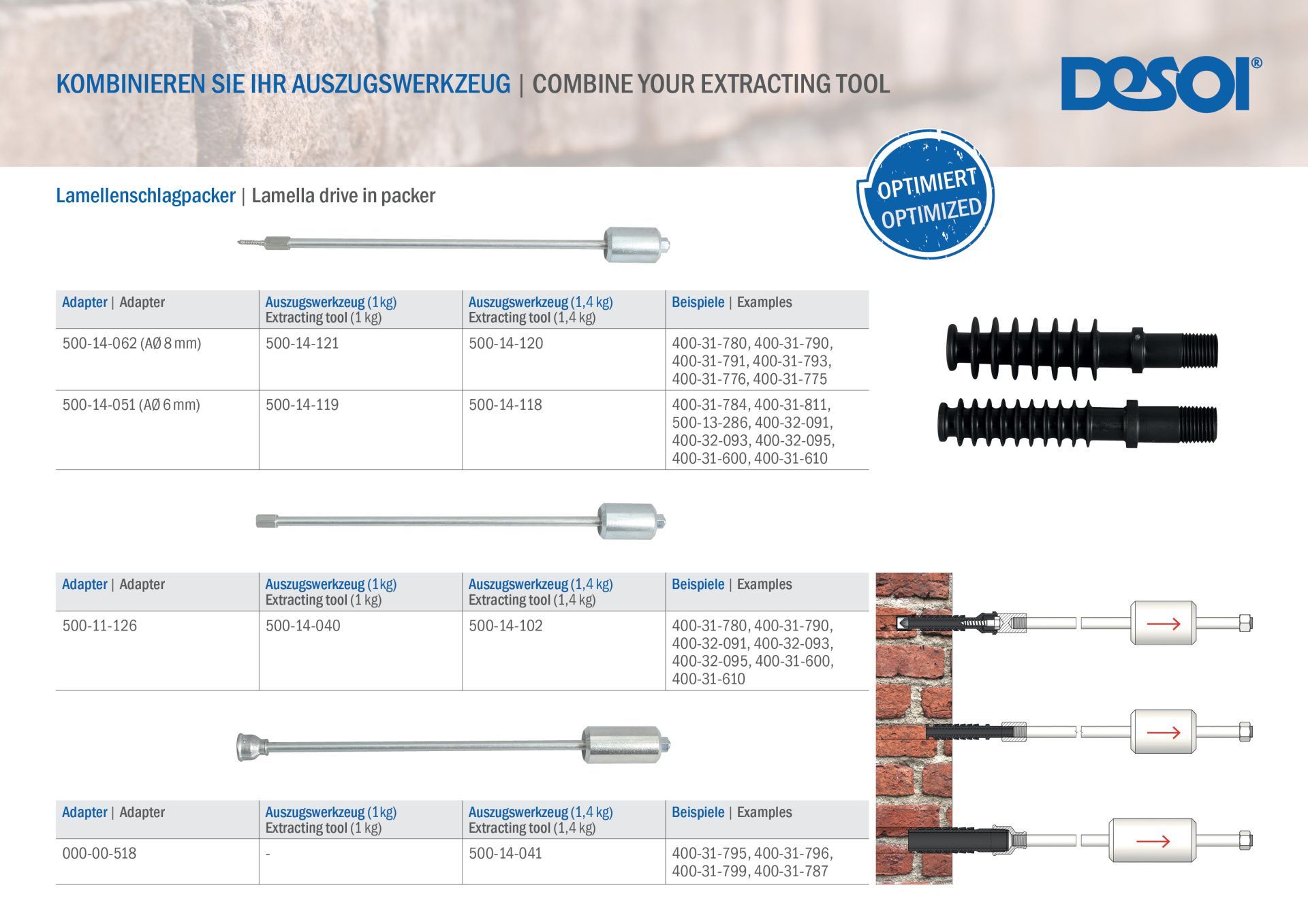

Extracting tool for lamella drive-in packer

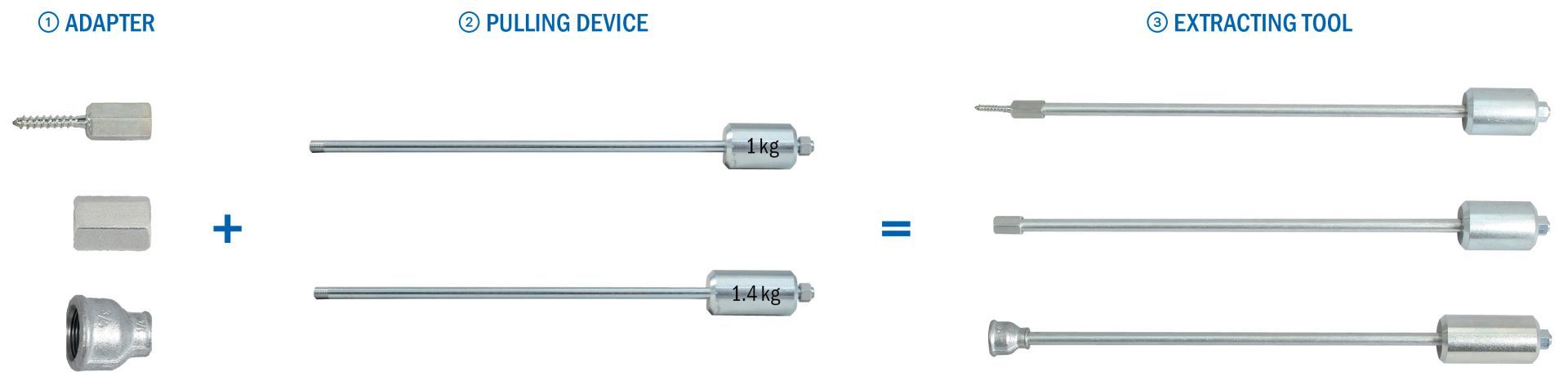

Combine your extracting tool

In order to remove lamella drive-in packers from the construction element there are different extracting tools available, varying to the type of the packers. The extracting tool is screwed in or on the lamella drive-in packer and the impact weight is moved powerful into the pull-out direction. Step by step the packer is removed from the construction element.- Basis: Pull rod

- Weights available individually between 1 kg and 1.4 kg

Advantages

- For the extraction of different types of packers

- All adaptors can be combined with both pulling devices according to the application

- Reusable product

- Easy handling

Extracting tool

Application